A ride on the “Desert Race” roller coaster is a must for all adrenaline junkies and technology enthusiasts! The 650-metre track with its impressive climbs and tight turns is covered in just 49 seconds. During the thrilling ride through the atmospheric desert backdrop at Heide Park Resort, passengers experience acceleration forces of up to 4.7 g – forces that are otherwise only felt by Formula 1 drivers.

“Our roller coaster uses the kind of catapult launch that is also applied on aircraft carriers. The coaster train sits on a sled that accelerates from 0 to 100 km/h in just 2.4 seconds. When the train reaches its maximum speed after 25 metres, the hook that connects the train and sled is released. The train then continues the rest of the way under its own power, using only the kinetic energy from the catapult launch,” explains Marcel Birke, Mechanics Manager at Heide Park Resort.

The power of hydraulics

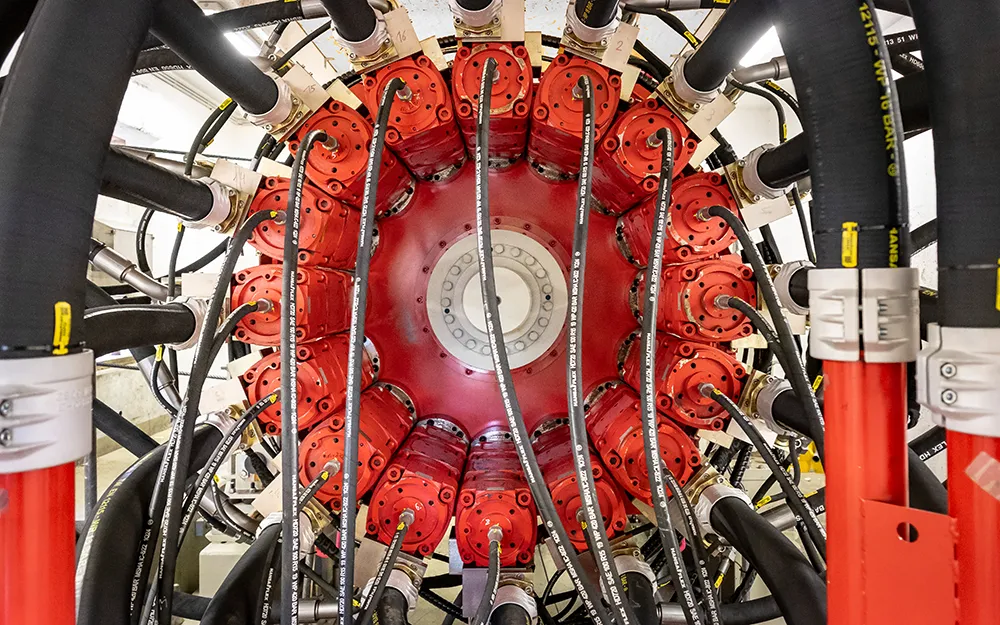

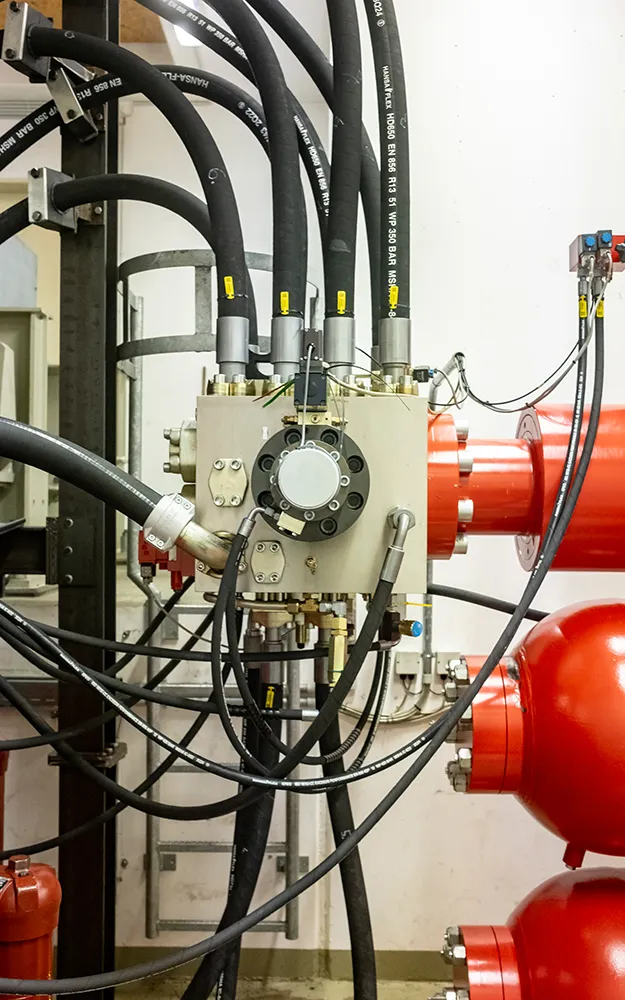

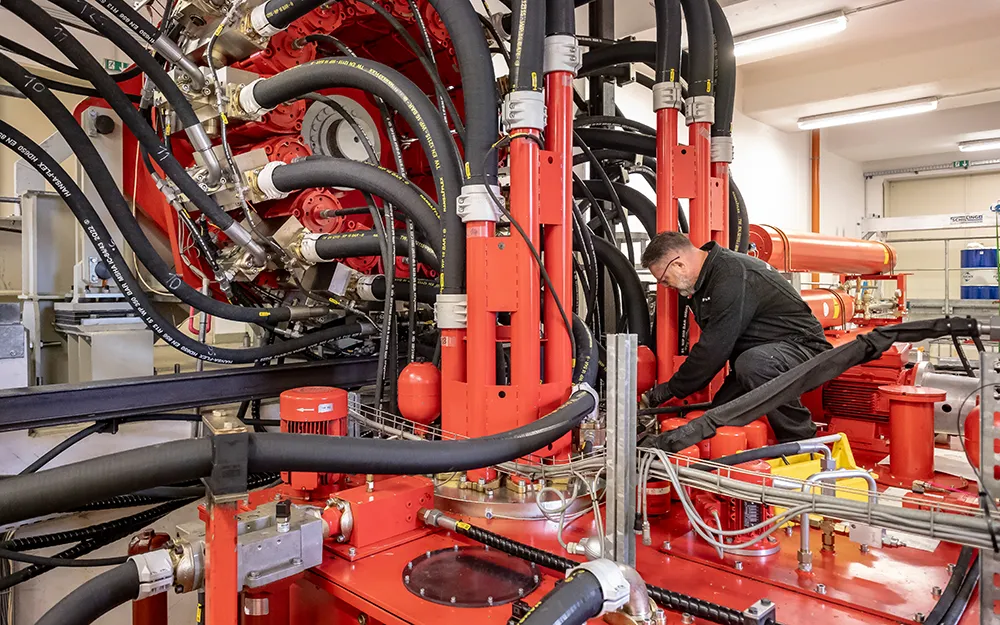

In order to ensure the catapult launch functions reliably even during very busy periods, Heide Park Resort relies on hydraulics. The heart of the system is a large cable winch that accelerates the sled and thus the 10-tonne roller coaster train at the start. The catapult launch places the highest demands on the hydraulic system. The necessary pressure is achieved by means of piston accumulators filled with hydraulic oil and pressurised nitrogen gas. Two hydraulic units compress the nitrogen. During the launch process, the valves of the accumulators are opened and the compressed nitrogen forces the hydraulic fluid into the 16 hydraulic motors that drive the cable winch at a pressure of around 300 bar. After the launch, the winch reverses direction and returns the sled to the starting position via the return cable, and the pressure accumulators are refilled. “The demands on the hydraulics are immense: in the peak season there are only two minutes between rides,” reports Birke. The sudden equalisation of pressure would normally cause the hydraulic fluid to foam. To prevent this, Heide Park Resort uses special hydraulic fluids and additives, as well as a 7,000-litre storage tank. “We also cool the hydraulic fluid, which would otherwise overheat due to the high pressures and volume flows,” adds Birke.

Maximum safety

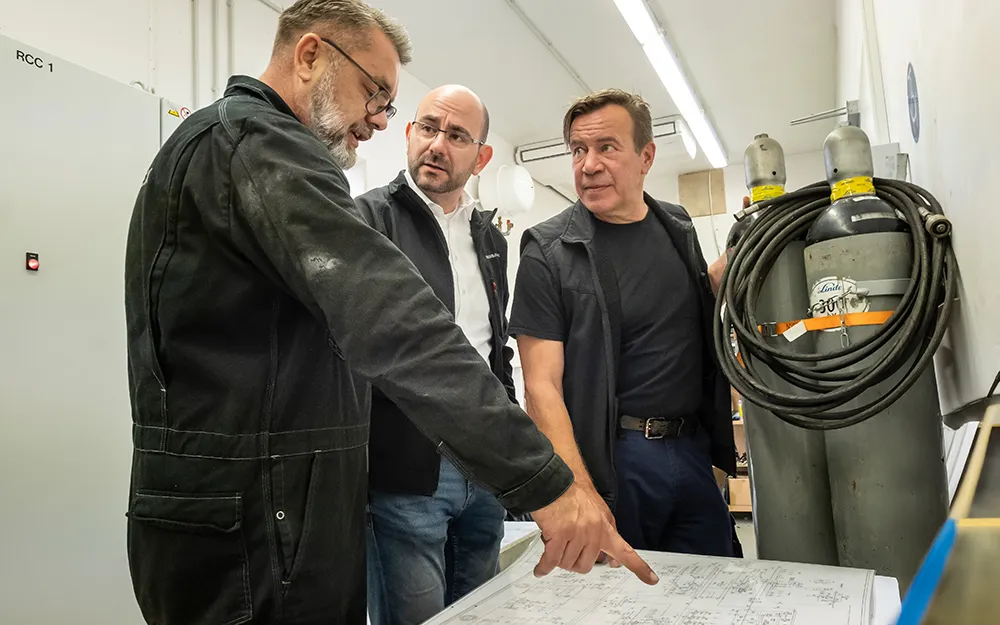

Safety is paramount at Heide Park Resort. The safety checks start as early as 5 o'clock in the morning, before the first guests board the “Desert Race”, which has by then been put through its paces, at 10 o'clock. In addition to the daily checks, more extensive inspections take place weekly and monthly. Added to this are the annual inspection by the Technical Inspection Authority (TÜV) and major maintenance of the roller coaster during the winter months when the leisure park is closed. Groszczyk and his team of 20 technicians use the My.HANSA‑FLEX customer portal for the annual inspection of the hydraulic hose lines required by Germany’s Social Accident Insurance (DGUV). “All the hose lines installed at Heide Park Resort are recorded there, and clearly assigned to the individual attractions and rides. Using a tablet, we can quickly access the technical data for each hose line and then conveniently enter the result of the DGUV test.”

Complete hose change with a well-rehearsed team

The regular change of all 200 hose lines of the “Desert Race” coaster is carried out by the HANSA‑FLEX Industrial Service. Even though the team has already worked in various leisure parks, connecting the hoses of a roller coaster is a welcome challenge for the technicians. “Working at HANSA‑FLEX is like the popular kids’ TV show with the mouse: we get to explore the most exciting areas that no one else can get into,” comments HANSA‑FLEX Service Manager Muhamed Grosonja with a twinkle in his eye. As all the hose lines are already recorded in the My.HANSA‑FLEX customer portal, the preparations go smoothly. The preconfigured hose lines are delivered on three Euro pallets, enabling the team in the roller coaster's machine room to get started immediately. The technicians produce smaller hose lines on site in their workshop vehicle. “We knew immediately that we were dealing with a well-rehearsed crew: the replacement of the hose lines went like clockwork,” says Birke, describing the HANSA‑FLEX team. The test run of the newly connected hydraulic system is successful at the first attempt: “Pressure and sealing are all good to go.”

Reliable hydraulics from a single source

Summing up the partnership, Stephan Thobe from the HANSA‑FLEX Sales department states: “We’re proud of the fact that Heide Park Resort places its trust in us when it comes to working on exciting installations where safety is a critical factor.” Marcel Birke particularly appreciates the wide range of products and services that the partnership provides him with. “HANSA‑FLEX is an important system partner for us. I have a central contact person whom I can turn to with any questions about hydraulics.” For example, HANSA‑FLEX is currently overhauling a three-stage telescopic cylinder for the leisure park which even when retracted is already over 6 metres in length. In other words, there is no shortage of exciting projects!

Mexico

Mexico