INFORMATIVE OIL ANALYSIS

Systematic oil analyses

Take a systematic approach based on comprehensive oil analyses

Determine all the information about the oil

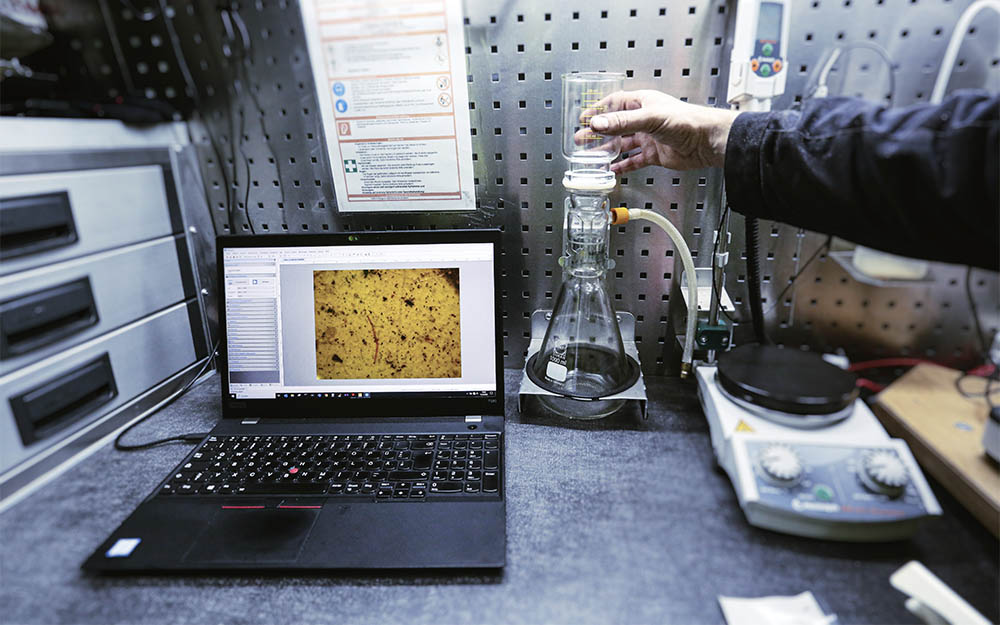

A check-up of your hydraulic system including a professional oil analysis provides all the important information about your fluid, such as contamination, mixing and ageing. The cleanliness level of the oil is also measured in accordance with ISO 4406. The oil analysis is performed by an accredited and certified independent laboratory. The HANSA‑FLEX fluid specialists interpret the results to produce specific recommendations. In this way you can rectify faults before they fully develop and cause damage.

Systematic damage detection

When damage occurs, you have to act quickly. Experienced HANSA‑FLEX fluid and hydraulics specialists search for the causes directly on site and immediately carry out a professional oil analysis. The results form the basis for detecting damage to components such as pumps, cylinders, hose lines and filters. Then the experts set about the specific measures required to bring your system back into working order. We can also plan and manage other work to keep your system operating smoothly over the long term, such as installing filters or flushing the hydraulics. We also support you in the implementation of preventative maintenance measures.

Comprehensive fluid management

Your oil analysis provides the foundation for optimising your system. It shows up any possible weak points and helps you to rectify them in good time. In addition to performing various measures such as cleaning or drying the hydraulic oil, HANSA‑FLEX Fluid Service can also implement other processes as part of fluid management. From defining the schedule of oil care processes to deciding on the servicing intervals, from monitoring the results of the measures right up to employee training: the experienced fluid and hydraulic specialists at HANSA‑FLEX are available at any time to answer questions and provide information about fluid management.

Professional oil analyses from experts

The HANSA‑FLEX Fluid Service professional oil analysis reveals all the important information your hydraulic oil contains

-

Perfect analysis

Oil analyses in the laboratory or on site give definitive information about the condition of the oil and the machine.

-

Reliable fault detection

Faults such as oil mixing, contamination or water in the oil are detected immediately.

-

Oil change timing

The optimum oil change interval is determined individually for each machine or plant.

-

Guaranteed quality

Quality checks after oil changes and performance of warranty services.

Contaminated fluid

These five factors are damaging to hydraulic oil

Contamination by solids

Water contamination

Undissolved air

High temperatures and shear

Oil mixing

Keep an eye on your oil with condition monitoring

- Present state analysis and basic planning

- Definition of limiting values to meet the hydraulic system requirements

- Selection and installation of oil condition sensors

- Configuration and setting up of data transmission paths

- Evaluation and interpretation of measured values

- Manufacture and installation of alarm devices etc.

What everyone should know about fluid management

Efficient oil filtering

Regular oil filtration ensures your production processes run smoothly and helps avoid damage to equipment, systems and machines.