Hydraulic oil is a crucial factor in the reliability and performance of machines. Whether in agricultural machinery, hydraulic drilling equipment, or machine tools, the oil ensures smooth power transmission, reduces wear on moving parts, and contributes to the long service life of the equipment.

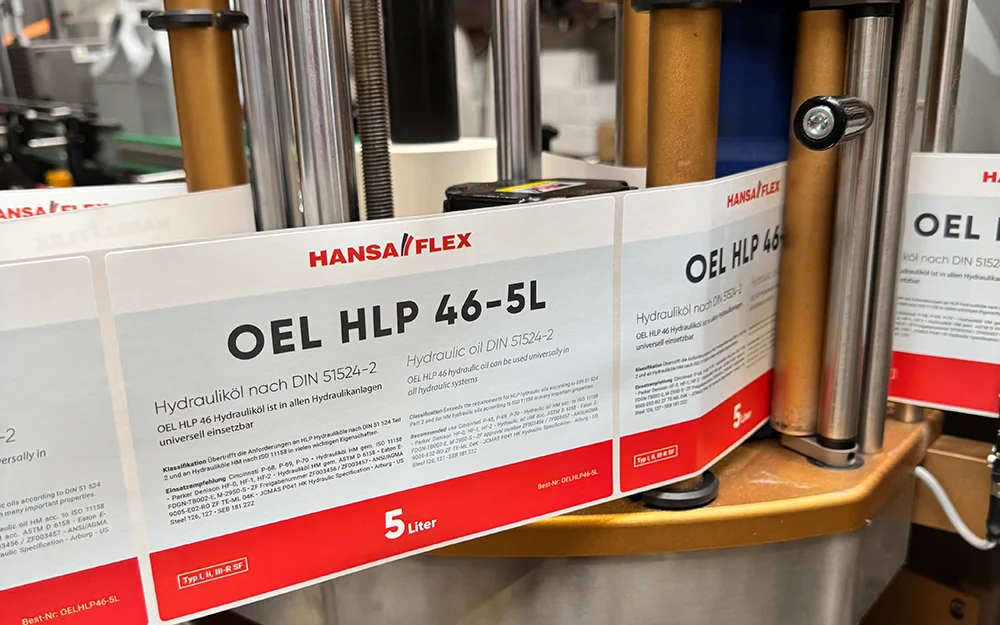

Do you need hydraulic oil, but not in large quantities? Then we have just the thing for you! We now offer our proven OEL HLP 46 hydraulic oil in a practical 5-liter container – ideal for anyone who wants flexible, clean, and easy refilling. This size is the ideal complement to our classic 20- or 200-liter containers, which are still available.

Only fill your system/machine with filtered hydraulic oil, e.g., using a bypass filter system or a filling pump.

Whether in workshops, agricultural engineering, construction, or industry: with the new 5-liter canister, you always have exactly the amount you need at hand – without compromising on quality.

Your advantages at a glance

- Compact & space-saving – Easy to store, transport, and use.

- Easy to handle – No spillage, no decanting, no hassle.

- Ideal for refills – Particularly suitable for smaller applications and individual machines.

- Highest quality – Our hydraulic oil meets all common industry standards and manufacturer specifications.

- Less waste, more cost-effectiveness – Buy only what you really need.

Perfect for many areas of application

- Workshops – For quick refills directly at the workplace

- Agriculture – Fits conveniently on the tractor or in the warehouse

- Construction companies – For compact machines and changing locations

- Private users & hobby mechanics – For occasional use, without large stocks

Consistent quality – new flexibility

Of course, the quality of our OEL HLP 46 hydraulic oil remains unchanged. It meets all relevant standards and specifications for reliable use in hydraulic systems. With the new 5-liter version, we combine this proven quality with maximum user-friendliness.

You benefit from clean, controlled dosing while saving time, space, and money.

Now available!

Get yours now and benefit from new flexibility in supplying your machines:

Hydraulic oil in 5-liter containers – the smart solution for professionals and practitioners!

Order online now or purchase directly from our branches!

Mexico

Mexico