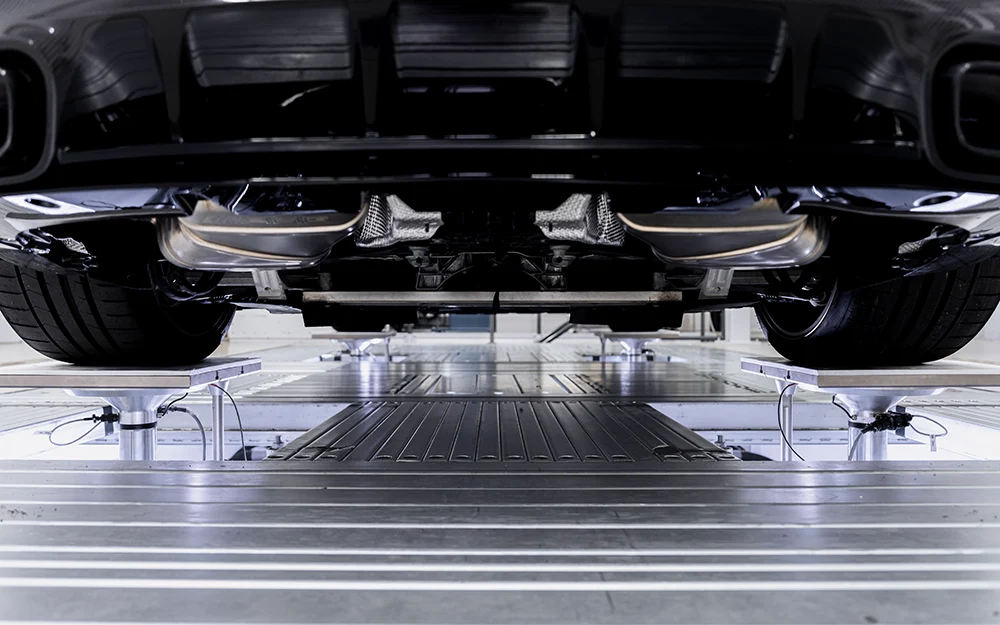

Whether it is Formula 1, Le Mans prototypes or series production vehicles: the chassis is crucial to the safety and dynamics of a car. Tests are indispensable for fine-tuning the coordinated performance of dampers, springs and other components. With its 7-post vertical dynamics test bench, TRE transfers the tests from the track into the testing hall.

The first chicane demands everything from the 500-plus hp GT3 class sports car. The Prima Variante is infamous for its narrowness. Drivers must brake from way over 250 km/h on the start/finish straight to “only” 70 km/h before very quickly mastering a challenging combination of a 90-degree right-hand bend followed by a tight left-hand bend. While the sports car follows its ideal line lap after lap with the precision of a Swiss watch, numerous sensors record the forces acting on the car’s chassis. The data collected from this test drive on the six km long circuit are used to analyse and optimise the way components such as dampers and springs work together. The goal: maximum vehicle dynamics with the car remaining safe and controllable at all times, even when approaching its limits.ug.

The in-house track

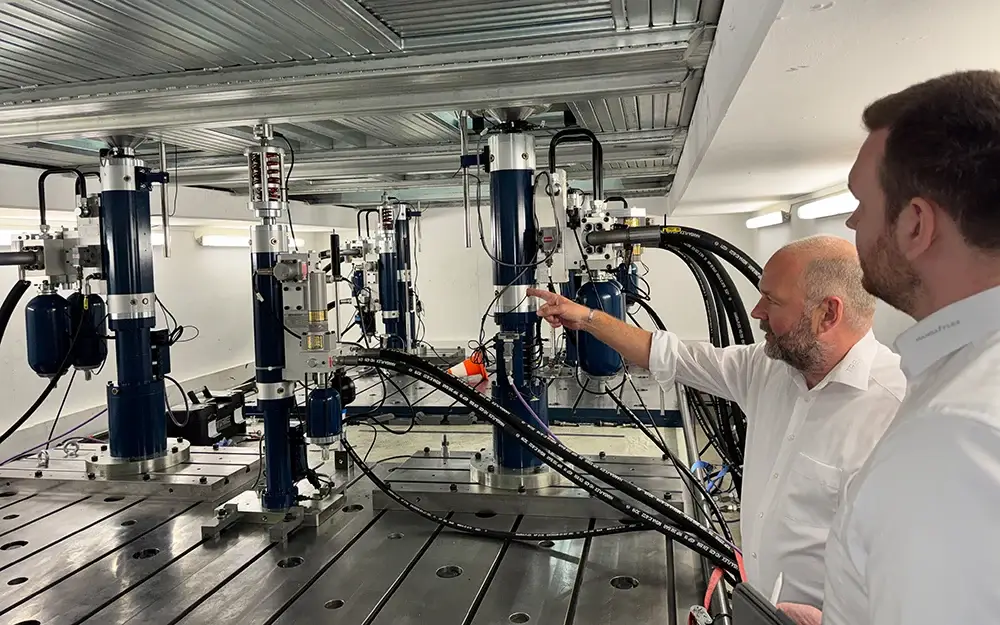

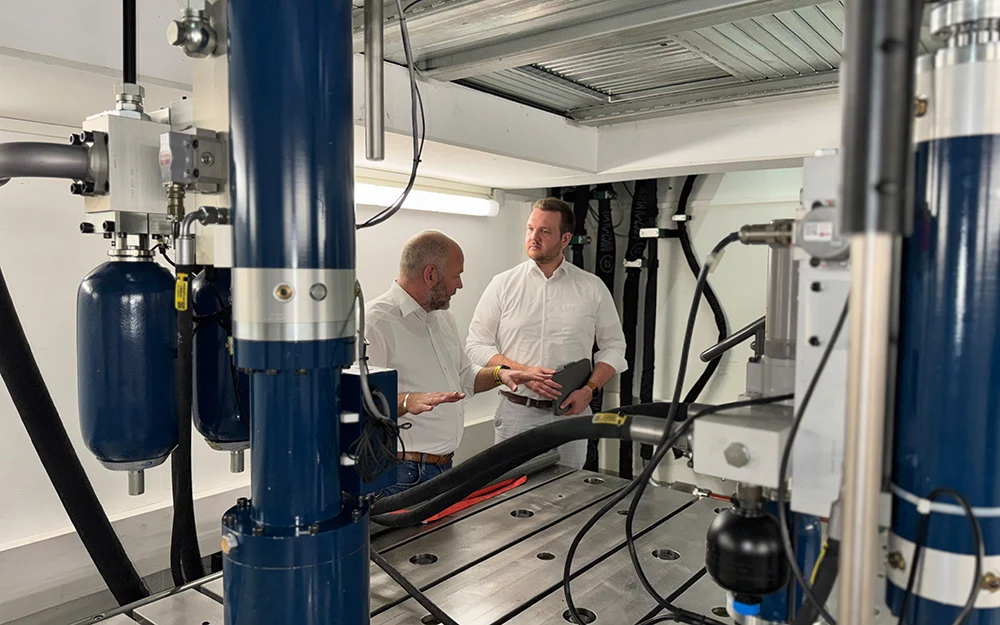

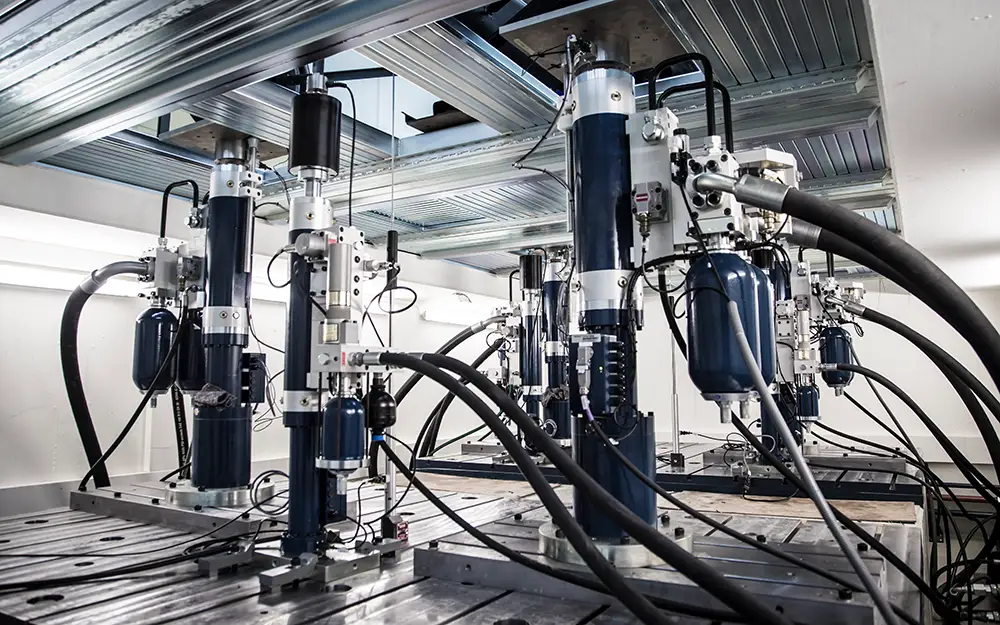

Anyone who thinks the above description is about a test drive on the Autodromo Nazionale di Monza is right. But also wrong, because this test does not take place on the legendary high-speed circuit near Milan but in Neustadt an der Weinstrasse. To be more precise, on a test bench at TRE GmbH. “Our vertical dynamics test bench allows us to analyse and optimise the chassis set-up under near-realistic conditions. The vehicle’s wheels are excited vertically by four hydraulic cylinders. Three additional cylinders simulate the aerodynamics as well as the pitch and roll behaviour,” explains Philipp Premel, Head of the Vehicle Test Lab at TRE. TRE could be said to bring race tracks from all over the world into its in-house laboratory: based on real measurement data or computer models, race tracks can be simulated on the test bench so that the chassis can be optimally adjusted for a wide range of different conditions. The advantages of these “track replays” are obvious: no track rental costs, no emissions, absolute reproducibility of the results free from the influences of weather, driver or mechanical wear. Automated processes permit faster test cycles, with up to 100 different damper settings tested per day. “We can simulate critical situations without risk for the driver or the vehicle,” adds Premel.

Motorsport in the blood

TRE stands for Team Rosberg Engineering. The company was founded as a development centre for vehicle components in 1997 by Formula 1 World Champion Keke Rosberg. The company is led today by his son Nico Rosberg, entrepreneur and Formula 1 World Champion 2016. TRE operates one of the few manufacturer-independent test benches. In addition to the material, time and cost savings, there is another advantage: absolute confidentiality, which the customers from Formula 1 greatly treasure. In addition to customers from various classes of motor racing, series production car manufacturers also rely on TRE’s know-how and years of experience. The 70 or more engineers working for the chassis specialist can, if requested, take over the whole value creation chain from conception, through design and prototype construction right up to simulation and testing. “The hydraulically operated test bench can be adapted for different vehicle types, axle loads and applications,” says Premel. Even manufacturers of agricultural machines can test and optimise the damping performance of their driver’s cabin suspension systems in Neustadt.

With hydraulics at its heart

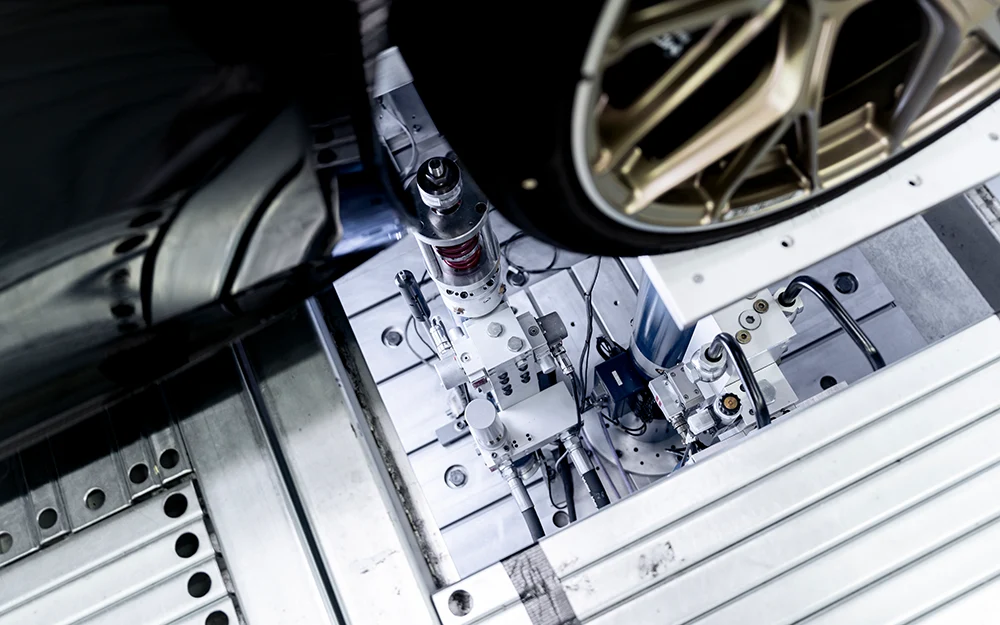

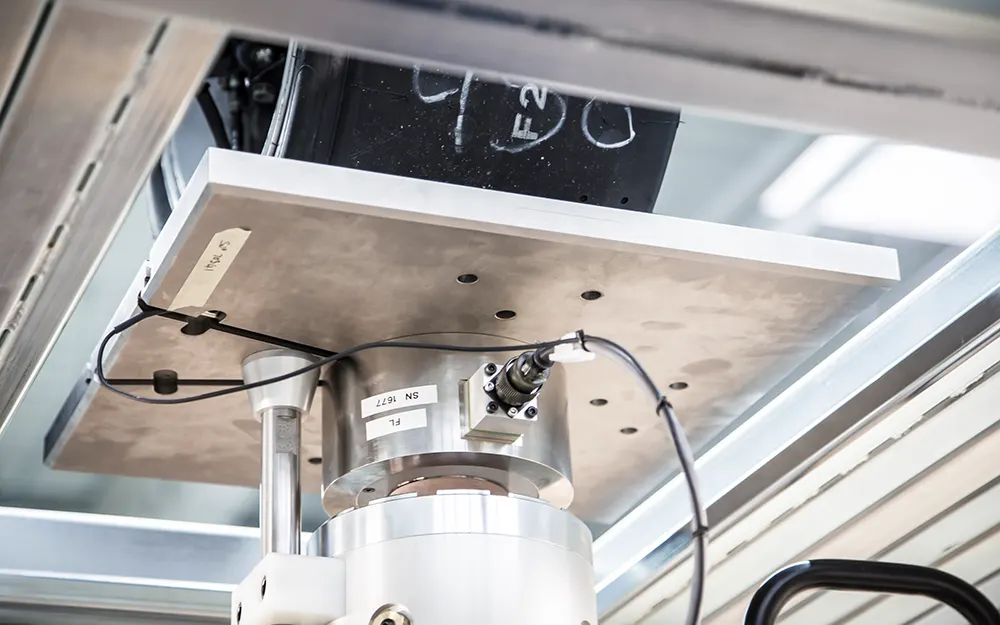

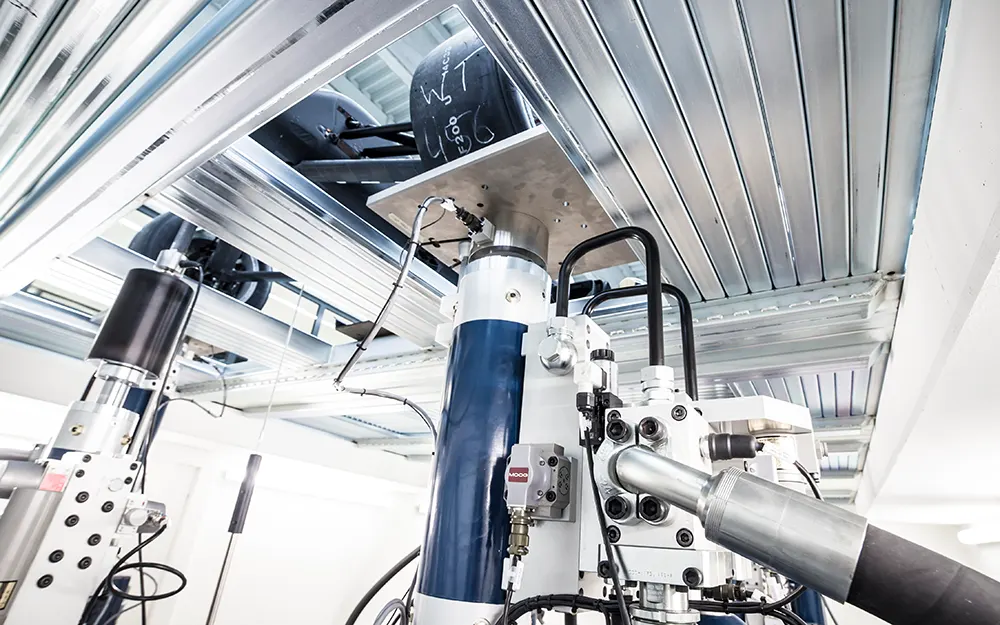

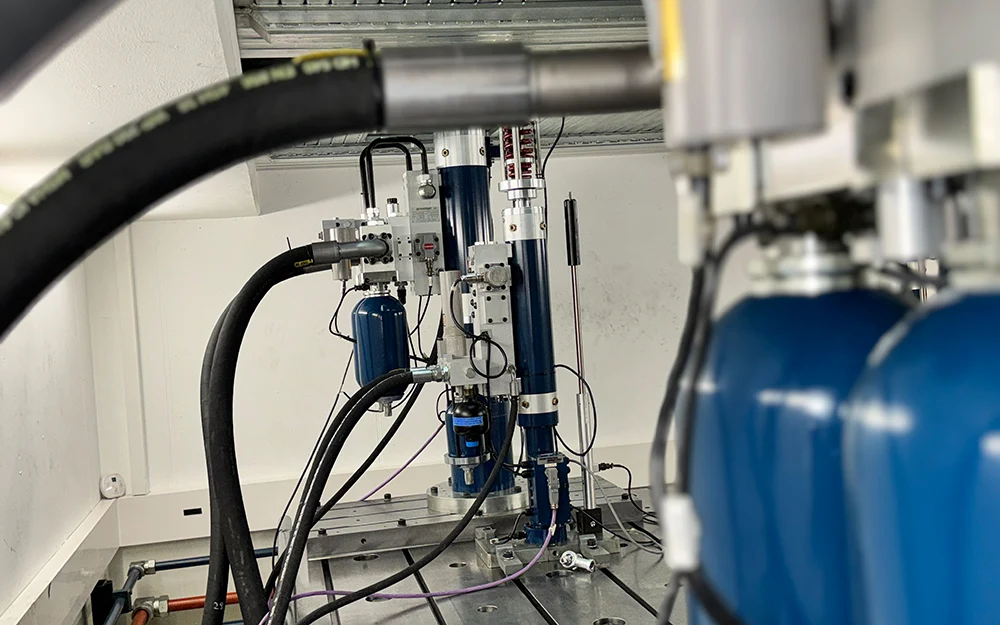

Hydraulics is at the heart of the 7-post vertical dynamics test bench at TRE. Two 90 kW pumps produce a working pressure of up to 280 bar, which moves the seven hydraulic cylinders on the test bench. The wheels of the vehicle stand on hydraulic cylinders that can each move 125 mm up and down to reproduce various road surface situations. Three more hydraulically operated cylinders simulate the behaviour of the vehicle about its longitudinal and transverse axes, for example, the dipping of the front or rear when braking and accelerating (pitch), the sideways leaning of the vehicle around curves (roll or yaw) and finally the downforce at high speeds. “We can even test at 250 km/h while stationary,” says Premel, as he gives an insight into the capabilities of the test bench. While the test bench has a traditional construction, the recipe for success at TRE lies in the control of the 7-poster. The seven hydraulic cylinders must be controlled by valves simultaneously in fractions of a second in order to exactly reproduce the predefined test scenario with all the different forces acting on the vehicle. Seventy-two sensor inputs record even the slightest movement on the chassis and vehicle in detail. “Collecting the data is only the first step. Interpreting the data and deriving the recommendations for optimisation are the real challenges, which is why TRE employs a large and expert team,” says Premel.

Genuine partnership

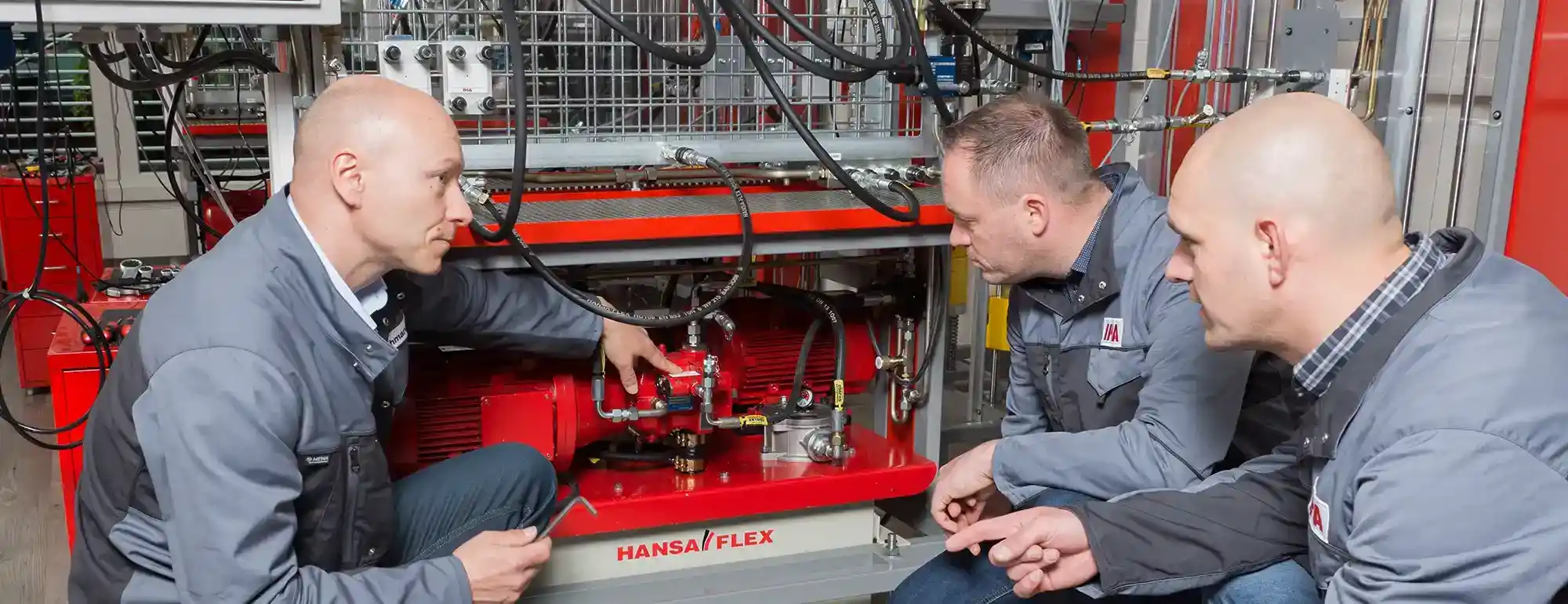

For hydraulics, TRE relies on HANSA‑FLEX as its system partner. “After some technical difficulties, we had been looking for a partner who could not only supply excellent quality but also provide a wide range of services in the field of hydraulics,” recalls Premel. The HANSA‑FLEX Industrial Service fitted out the complete test bench with new hydraulic hose lines. Components that the customer’s own engineers replace can be quickly and easily ordered thanks to X-CODE. In other cases, the customer can call on the Mobile Rapid Hydraulic Service. TRE particularly appreciates the quick response times, which reduce the amount of costly downtime of the test bench to a minimum. In order to focus on detecting imminent failures at an early stage, HANSA‑FLEX also performs the scheduled maintenance of all the hydraulic hose lines and pressure accumulators in accordance with DGUV requirements. The HANSA‑FLEX Fluid Service is also involved in failure prevention. The analysis and filtration of the hydraulic oil ensures that no contaminants adhere to the hydraulic cylinders. Given the high working pressure and the rapid, precise movements of the cylinders, this measure is practically indispensable. “We are always happy when we are allowed to provide a comprehensive service to the customer and see how our various products and services seamlessly coordinate with one another,” says Sebastian Nitzgen, Area Sales Manager HANSA‑FLEX. Philipp Premel values the calm character of the partnership above anything else: “If we very seldom see our hydraulics service provider here on site, we are safe to conclude that HANSA‑FLEX has done a really good job and breakdowns have been reduced to a minimum.” It is not only innovative services and a passion for quality without compromise that draws the two companies together. They also encourage the engineers of tomorrow through the Formula Student programme. The Formula junior teams are allowed to use the test bench at TRE at cost price and receive comprehensive advice and assistance from the chassis specialists: “We want to pass on our enthusiasm for motorsport and our experience to the next generation.”

Mexico

Mexico