“Most failures are traced to constructional errors”… according to our experience, which we have gathered dealing with customer complaints, delivering training courses and providing advice. Our analyses show that the percentage of failures due to these errors and the resulting use errors is around 65 %. Often the hydraulic hose line chosen is not appropriate for the application. It can also be down to the wrong hydraulic hose line cross section, usually too small, its size having been chosen to suit the static pressure, which is hardly ever the situation, instead of the dynamic working pressure. Other causes include: pressure peaks in the system not considered, excessive system temperatures, which can prematurely age hydraulic hose lines and considerably reduce their service life; confined installation conditions leading to hoses with bends of less than the recommended minimum bending radius and an adverse effect on their longevity.

About 34 percent of these errors are made during maintenance. They arise in repair work, such as replacing damaged hydraulic hose lines, because parts are replaced like-for-like in most cases. Getting to the root of the problem – the Why – just does not happen. The highlighted main causes of damage arising out of constructional errors, such as mechanical damage, sharp bends, tensile loads, squashing or unsuitable medium, are not being effectively addressed.

Another point of criticism is the number of regular checks for early detection of damage to operating hydraulic hose lines that are not carried out. These checks allow maintenance to be preventative and contribute to increased machine availability. A simple visual inspection includes checking whether the hydraulic hose line outer layer is in fault-free condition, i.e. shows no cracks, bubbles, wear or deformation.

Also checked here is whether, for example, the installation was done correctly, avoiding sharp kinks and too much tension or torsion. Checking for leaks and incorrectly installed fittings is important too. Preventative intervention by performing and keeping proper records of visual inspections contributes to reducing corporate liability risks.

Where do designers go wrong?

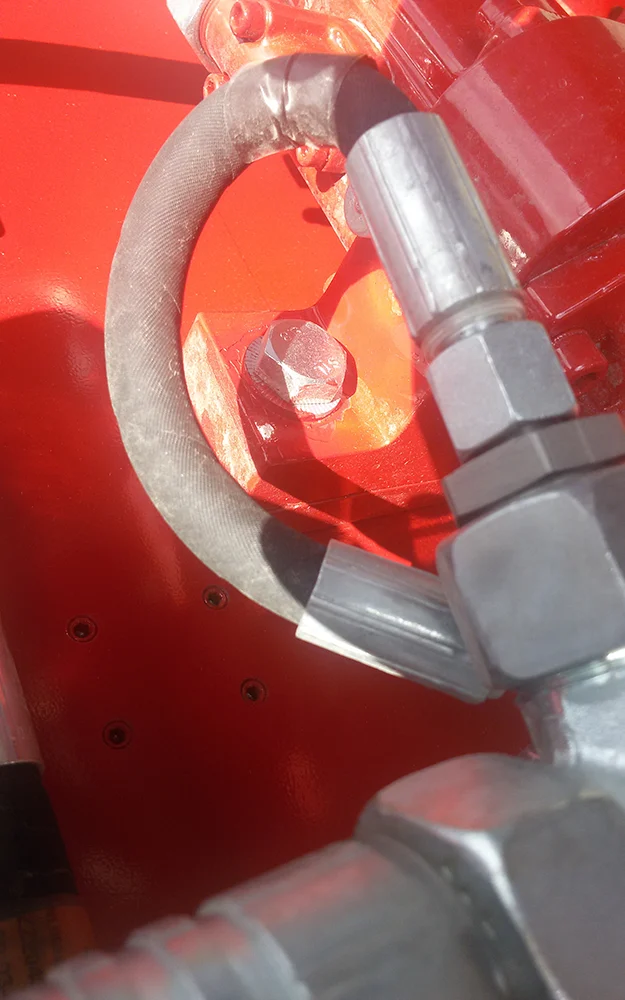

In many cases, designers are not aware that a hydraulic hose line is an important engineering element that must be appropriately designed and selected for its use within an extremely diverse range of applications. A hydraulic hose line is and remains a wear part and cannot be considered as an everlasting component. The designer must know the limits of products with respect to their specific fields of use. Important factors such as the installation situation, combinations of hydraulic hose and connection fittings and the compatibility of the medium with the inner layer of the hose are important criteria for the designer to keep in mind. Furthermore, a primary consideration should be that hydraulic hose lines operating under unfavourable conditions are unlikely to achieve their maximum possible hours of operation. The maximum working pressure, temperature and minimum bending radius contribute to creating these conditions. If the designer adopts a solution that operates close to its loading limits, the product ages more quickly and therefore needs to be replaced prematurely.

Note: the higher the temperature and pressure load, the higher the likelihood of premature failure of the hydraulic hose line.

A further complication is that constricted installation situations often prevent the fitter from installing the component in accordance with the requirements. Replacement cycles must be adjusted accordingly and highlighted in the operating manual left with the user.

How does this look in practice from the maintenance angle?

Maintainers often have the problem that they cannot begin to appreciate what correct installation or installation in accordance with the requirements is because the limits and peculiarities of the engineering element, here the hydraulic hose line, have not been made clear to them. As a result they lack the necessary specialist knowledge of hydraulic hose line technology. How would a maintainer gain this knowledge when hydraulics with all its peculiarities is not even officially recognised as an occupation that requires formal training? Knowledge of bending radius, torsion, temperature resistance, changes in length of a hydraulic hose line under pressure, as well as kinking or correct tightening up of hydraulic hose fittings, is frequently learned only from hearsay, i.e. in on-the-job conversations.

Likewise, the date when a hydraulic hose line is due to be replaced is often unknown. Incorrect product choice or installation not in accordance with the requirements can lead not only to damage of the product but also to the failure of a hydraulic hose line, sometimes with serious damage to property or severe personal injury. A designer or a maintainer with the appropriate specialist knowledge of hydraulic hose line technology can considerably extend the useful life of a hydraulic hose line. The reward is higher machine availability, operational efficiency or both.

We are always asked in our seminars: When do hydraulic hose lines need to be replaced? Is it necessary to specify a time-dependent replacement interval? Assuming the answer to the last question is yes, how should the replacement interval relate to component type and loading? Since these specific questions come up time and time again, it is clear that hydraulics should be urgently acknowledged as a recognised occupation requiring formal training.

The answer to the questions is provided by our legislators, who require that manufacturers and operators of hydraulic equipment are obliged to provide details of the inspection cycles and replacement periods of hydraulic hose lines. This must be done by manufacturers of hydraulic equipment in their risk assessments and/or operating manuals, and by operators (employers) in their own documented risk assessments. In establishing the useful life and the replacement interval of individual hydraulic hose lines, the above organisations must take into account the specific requirements and recommendations of the manufacturers of the hydraulic hose line and the machine. Moreover, the equipment manufacturer’s and operator’s experience of the specific conditions of use and the results of inspections performed to date are also significant. Guidance values for the recommended replacement intervals are summarised in DGUV Rule 113-020.

In this document, the requirements relating to hydraulic hose lines are given for two requirement classifications: normal and higher. The recommended replacement intervals, which are based on the practice adopted to date are listed accordingly. An example: for higher requirements due to increased operating hours, for example in multi-shift operation, or due to short cycle times of the machine or pressure pulses, a replacement interval of two years is recommended. For normal requirements, the replacement interval is 6 years. This must be accommodated and considered appropriately in the design of the equipment. If the recommended replacement schedule is not observed and a hydraulics-related safety incident occurs, then the question will be asked as to why. The legal consequences of breaches of duty by employees in their activities at work are based on the concept of employee liability. The degree of blame attributable to the employee relates to the breach of duty and not to the amount of damage. With the help of expert witnesses, the judge decides whether minor negligence, moderate negligence or intent and/or gross negligence applies. The contributory negligence of the employer is similarly investigated for organisational blame.

It is also important that maintainers in practice and designers when writing an operating manual know what should be considered when changing the oil type of a machine already in use to a bio hydraulic oil. Or does the rule “New oil – new hydraulic hose lines” apply here? There are clear guidelines in DIN ISO 15380-2024 for changing from mineral-based to bio oils. Experience has shown that the suitability of elastomer components such as hydraulic hose lines and seals should be checked when planning a change of mineral oil type or a switch to a bio oil. It is crucial to understand that bio oils from different manufacturers may not be mixed nor may they be mixed with mineral oils. The oil supplier or manufacturer of the bio oil specifies the residual mineral oil content. To comply with legal obligations in the German Water Resources Act (WHG), the guidance in DIN ISO 15380 that the residual mineral oil content is less than two percent must apply. If the residual mineral oil content is more than two percent, then the biological degradability requirements are not met. It is not sufficient merely to empty the tank; the system must be completely flushed several times. To comply with legal obligations, the residual mineral oil content in the system must be documented by an independent oil laboratory. This is often also demanded by local authorities in their council contracts. It would be incorrect to say that hydraulic hose lines always need to be replaced following a switch from mineral to bio oil. However, when such a switch is made, the hydraulic hose lines must be opened and flushed through with the intended bio oil. At the same time, the hydraulic hose lines must be checked for compatibility with the bio oil. Hydraulic hose lines showing signs of ageing must always be replaced. In every case, the proposed switch must be discussed with the hydraulic hose line manufacturer. In addition, filters, seals and coatings, including on the insides of tanks, must be checked for compatibility. Also to be considered: biologically degradable hydraulic oils have different solvent properties to mineral oils and therefore have a cleaning effect on deposits in the system. In order to avoid clogging of system components or sticking cylinders, filters must be checked and replaced after a short time.

Old, encrusted but still effective seals may show signs of leakage quite soon after the switch.

We are often asked whether oil care has an effect on the longevity of a hydraulic hose line. The answer to this is always a clear yes – because the enemies of hydraulic oil are also the enemies of a hydraulic hose line. The primary factors here are oil contaminated by free air and water, excessively high oil temperatures and mixtures of different oils. In the latter case, the question is not about miscibility but about compatibility with one another! Following a well-conceived oil care programme with an appropriate filter concept clearly extends the useful life of hydraulic hose lines, with the same benefits applying to the whole hydraulic system.

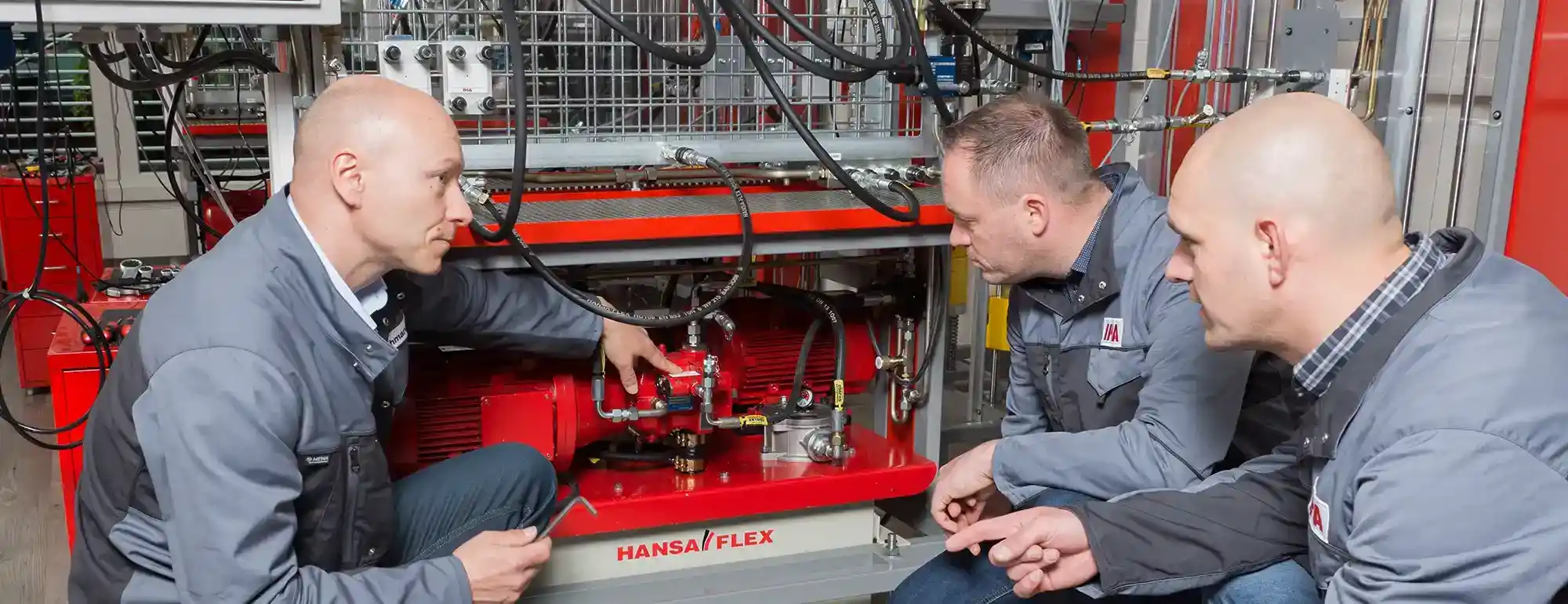

Many factors can affect hydraulic components. For the reasons mentioned above, more and more companies are outsourcing the required hydraulic hose line inspections to a specialist service provider. Often an early visual inspection carried out by someone trained in the field can prevent a later failure of the hydraulic hose line. The obligation to monitor should also be seen as a constituent part of preventative maintenance. But how is the cooperation on the operating company side with a service provider regulated and what are the employer’s obligations to monitor? First of all, it should be ensured that the service provider has the inspection performed by an authorised person qualified to conduct inspections. The employer should ask to see the authorisation. It is also important that the inspection is documented in detail; it is not sufficient simply to write something like “All hydraulic hose lines have been inspected”. All visually inspected hydraulic hose lines must be assigned with a marking individual to that component, and the documentation must show whether it is in the required condition or should be replaced.

Why? Because every hydraulic hose line has a different task, is subjected to different loads and therefore must be inspected and assessed individually. The employer should have a person suitably trained in hydraulic line equipment who evaluates the service provided with regard to inspection and documentation.

Conclusion: the design features and maintenance of a hydraulic system have a considerable influence on its useful life!

-

Ulrich Hielscher

Managing Director Internationale Hydraulik Akademie GmbH

Mexico

Mexico

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/9/4/csm_Bild_1.2_Unterschreiten_d.zul._Biegeradius_6fff7d4e26.png)