There is no more suitable place for an interview with Lelio Arlt than a vehicle from the Mobile Rapid Hydraulic Service. Not least because the qualified production and automation engineer has led the Mobile Service division at HANSA‑FLEX since the middle of the year. In the interview, the Austrian explains why HANSA‑FLEX has reorganised the division, why the Mobile Service is much more than just “fast hose” and what goals he is aiming to achieve with his team.

In what fields is the Mobile Service active?

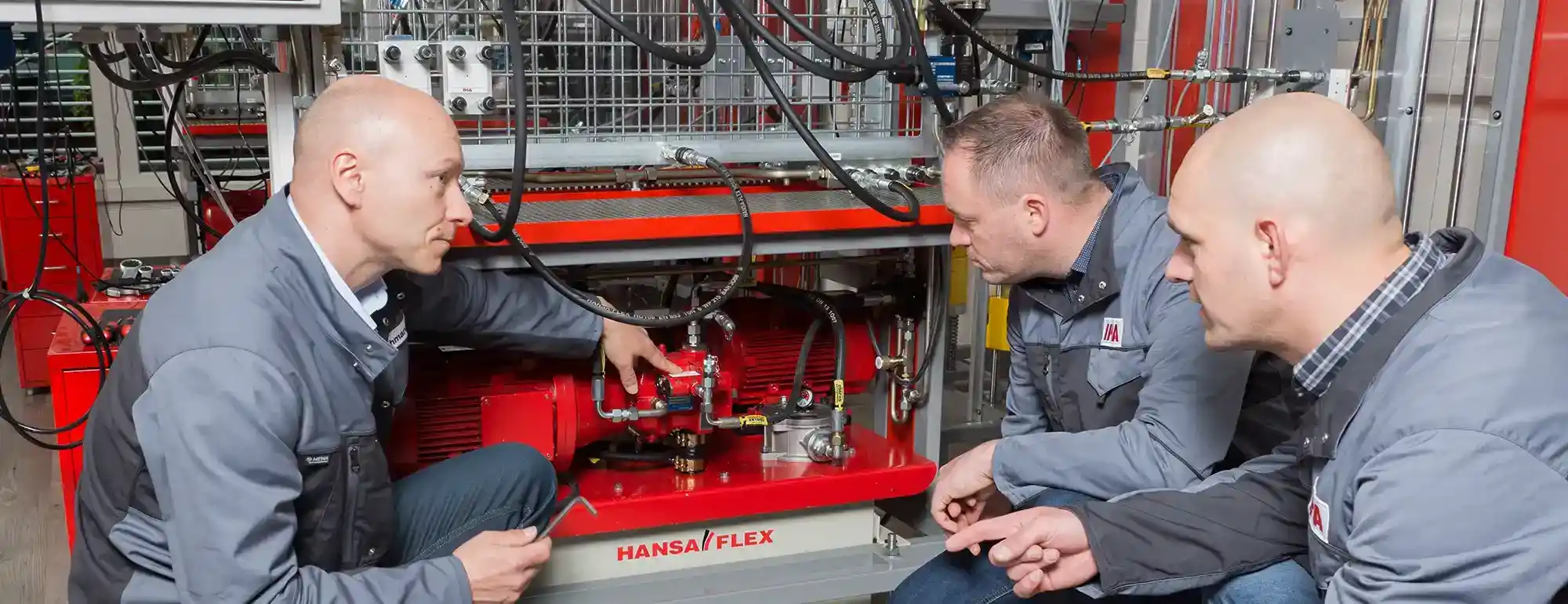

The Mobile Service stands on three pillars. One of these is the Mobile Rapid Hydraulic Service, our 24/7 emergency service for the speedy replacement of hydraulic hose lines directly on site at our customers’ premises. The second is the Industrial Service, which carries out planned maintenance, DGUV inspections and, of course, the installation of hoses and pipelines on demanding major projects. Third is the Fluid Service, which is at the centre of everything to do with hydraulic fluids. In addition, there's the Container Service for large construction sites. The services are wide-ranging, and the potential is great – both for us and our customers.

What makes the Fluid Service so special to you?

As system partners, we are responsible for our customers’ machines and plants. By means of oil analyses, the Fluid Service is able to monitor the condition of a machine or a plant, give advice about the potential risks and take the appropriate measures at an early stage, for example, filtering the oil or flushing the hydraulic circuit. I never cease to be fascinated by how we are able to use oil analysis – a relatively simple matter - to support preventative maintenance and, for example, by analysing the particles in the oil, proactively prevent costly and time-wasting stoppages of our customers’ operations. This pays off in terms of sustainability because the best repairs are those that do not have to be carried out.

How many people are employed in the Mobile Service?

In Germany, the Mobile Service has 280 service vehicles, 25 service centres and over 350 employees. This makes us one of the largest service networks in the industry.

Why is HANSA‑FLEX restructuring the division?

The Mobile Service plays a key role at HANSA‑FLEX. Not just because of our size, but also and primarily because we are the quick problem solvers for our customers, many of whom then go on to outsource further work to us, such as predictive maintenance. We are an independent division, which increases our agility and allows us to implement new services all the more quickly. It is my responsibility to further develop the division strategically and take it in the direction of sustainable growth. Part of this task is to ensure that we further optimise our processes, rethink structures and make much better use than before of synergies between the various services we offer.

What specific goals do you seek to achieve?

We have a clear goal: we want to continue to grow profitably and establish ourselves as a leading system partner for hydraulics for the long term. We are the only system partner to cover the whole field of hydraulics and to do so comprehensively both in width and in depth. However, that also means that we must continually expand our offering in the area of mobile services and make further progress on our journey to digitalisation. This innovative strength is an immutable part of the HANSA‑FLEX DNA: I work with a highly qualified and motivated team, who welcome being set new challenges. Feedback from the market as well as from our own ranks indicates that we are on the right path.

How have our customers reacted?

In the past, many companies saw us initially only as an emergency service because our other services were not as well known. Today, more and more companies entrust us with preventative maintenance, servicing and the legally prescribed inspections. Many of our customers ask us to undertake the whole of their hose management. This outsourcing creates certainty and relieves the workload on our customers’ employees, which is a big advantage in these times of skilled labour shortages.

What new services have you developed to date?

Continual improvement is the basic principle at HANSA‑FLEX, and the results show both in the detail and in the bigger picture. Two examples: we have modernised our service fleet and now use additional and, for the moment, parallel rechargeable battery packs instead of the earlier underfloor generators to supply electrical power to the mobile workshops. This means we can now work in low-noise and emissions-sensitive environments. In the Industrial Service, we are always looking to see what specialist skills we need to offer in order to best serve our customers. We are now in the position to undertake very complex and challenging projects, for example, hose line and pipeline installation in particularly hot environments. Sounds banal, but it is not. It makes me really proud to see how we have all further developed as a team.

Where does your passion for hydraulics come from?

I not only have many years’ experience in industry and logistics but also a very personal connection to engineering: I spent my childhood on a farm. Whether felling trees, repairing an engine or working with a tractor: from an early age, I have been excited about machines, and hydraulics certainly played a big role.

What is your personal motto?

It does not help to just think about a problem. Someone has to actually tackle it. That works well only if you have good people. To me, this is what constitutes the essence of HANSA‑FLEX: a genuine hands-on mentality which focuses on problem-solving and is embedded in a comprehensive concept for customer support.

Mexico

Mexico