The efficiency and reliability of hydraulic systems are crucially dependent on the proper performance of the maintenance and inspection of their components. The inspection of hydraulic hose lines, which are particularly important to these systems, is regulated in numerous publications, guidelines and operator obligations. However, the inspection of pipelines, threaded connections and fittings as well as other components such as attachments and accessories is often overlooked.

The effects of external influences such as corrosion and mechanical wear are frequently underestimated, although they are crucial factors that can adversely affect the functionality of the machines. Risk analyses as well as scheduled inspection, replacement and maintenance must be performed in order to avoid damage to and failures of these systems.

In the first part of our HOW TO series, we focus on the topics of inspection intervals and methods.

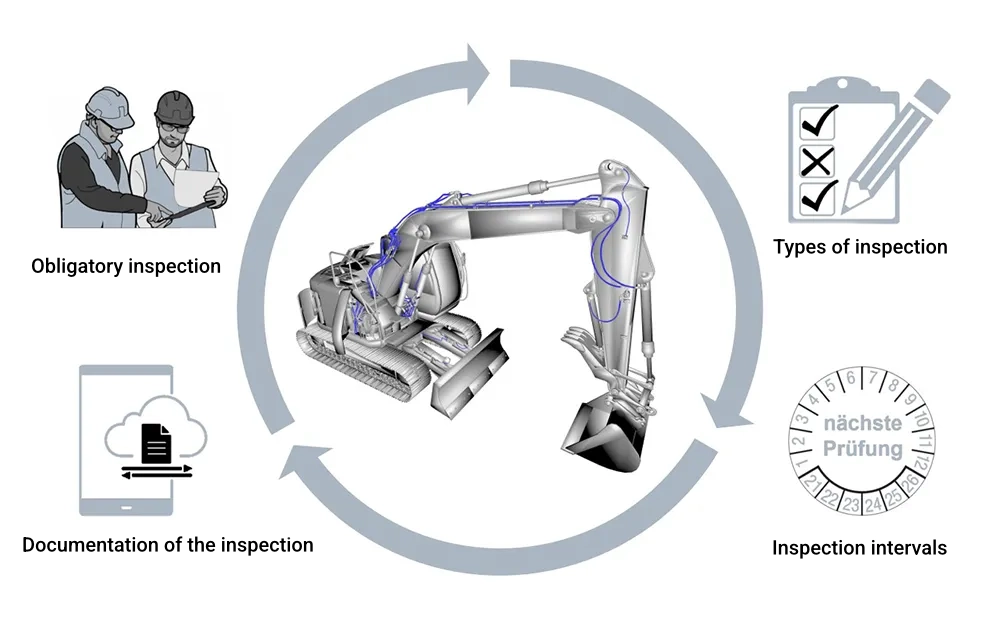

The German Ordinance on Industrial Health and Safety §14 (BetrSichV) clearly defines the requirements.

- Obligation to inspect: Work equipment and systems requiring monitoring must be regularly inspected.

- Types of inspection: Before bringing into use (commissioning inspections), recurring inspections during operation and extraordinary inspections after incidents.

- Inspection intervals: These vary in accordance with the hazard potential and type of work equipment.

- Documentation of inspections: The results of the inspections must be documented and made accessible.

- Responsibility: The employer is responsible for safety and observance of the inspection requirements. Inspections may be performed only by authorised persons.

Save the date: Inspection intervals are the key

Inspection intervals set out the time periods between visual or technical inspections of components. The hydraulic components of a system are constantly under load. Depending on the conditions of use, this can adversely affect their functions and, if neglected, even lead to component failure.

In the case of hydraulic hose lines, problems are frequently caused by the natural ageing processes of the elastomer material, which are accelerated by ozone and UV radiation. There are detailed instructions, rules and recommendations for the regular assessment of these components by an authorised person qualified to conduct inspections and for their replacement.

Hydraulic components such as screw fittings and, in particular, metal pipework with bends are often neglected when performing maintenance measures. This can also adversely affect component functions due to corrosion or mechanical wear. Regular checks as part of inspections are therefore expressly recommended.

Above all, we recommend that the corrosion resistance of pipelines and fittings is monitored and a visual inspection performed at regular intervals. These inspections aim to detect signs of wear, corrosion or other damage at an early stage to avoid more serious failures.

HOW TO: Methods of inspection for use directly on site

1. Visual inspection for corrosion and damage

What to do: Check pipelines and hose lines, screw fittings and pipework with bends for rust spots, detached coatings, discolouration and cracking. Pay particular attention to transitions, welds and bends.

Tip: Clean the pipework by wiping with a cleaning cloth. This will make rust, traces of oil and other abnormalities easier to see.

2. Tactile inspection

What to do: Run your hand over the component surface (do this only after the hydraulic system has been shut down, allowed to cool and depressurised!). Feel for irregularities such as burrs, bubbles, indentations or rough patches.

Aim: To find early signs of corrosion or material deformation.

3. Moisture or leakage checks

What to do: Specifically check suspect areas for leaks – either with a paper towel, leak detection spray or a soap and water solution.

Paper towel method: Wrap the paper towel around the suspect area and look out for moisture or discolouration.

Leak detection spray: Spray onto the affected area – if bubbles form, there is a leak.

Alternative: Apply soap solution (water and a little detergent) from a spray bottle to reliably show leaks, likewise by the formation of bubbles.

Tip: Particularly suitable for oil, water or compressed air leaks

4. Shake or tap test

What to do: Using a small plastic hammer or short wooden handle, carefully tap on the pipeline. Vibrations or a muffled sound can indicate a loose pipeline support or creep corrosion.

Important: Do not use this method on delicate systems or systems under pressure!

5. Fastening and position check

What to do: Visually inspect fastening points such as pipe clamps, brackets, insulating fittings. Check that everything is firmly seated and that no excessive vibrations occur.

Aim: To avoid premature wear due to loose fastenings.

6. Observe the manual or instructions

Use any instructions or checklists provided by the manufacturer of the machine or system when assessing operational safety

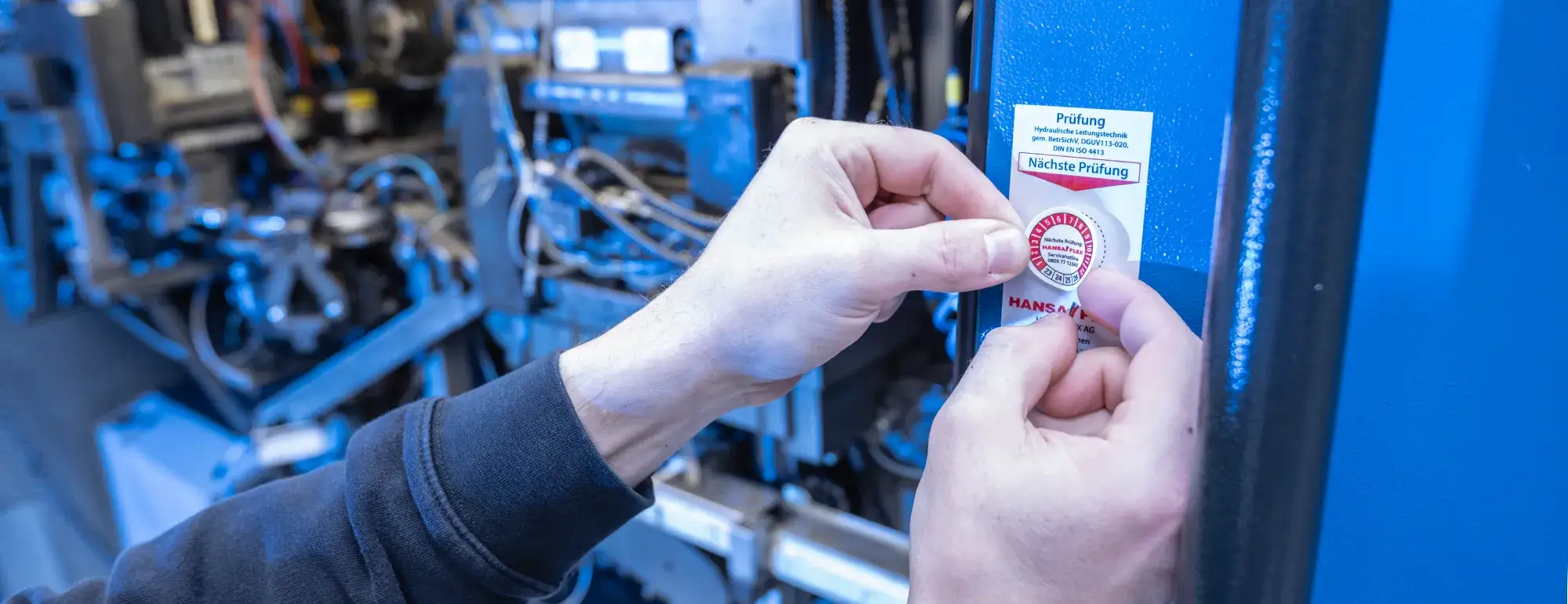

An inspection without documentation is not an inspection

Every inspection must be recorded in writing immediately following completion. There is no guidance about the format of inspection documentation. While an Excel table may be sufficient for small machines, we recommend digital solutions, e.g. the HANSA‑FLEX X-CODE Manager, for larger machines and systems. These solutions provide legal proof of inspection and a logically structured and efficient means of administering inspection records. A further advantage: Digital solutions enable maintenance or audit personnel to react quickly whatever the location and machine.

A paper copy of inspection record is signed by the inspector – an authorised person qualified to conduct inspections – and countersigned by the operator of the machine or system.

-

Sven Bötjer

Product Manager Pipe and Special Fittings,

Accessories and Tools

Mexico

Mexico