Broad horizon, in-depth technical understanding: as a technical adviser, Heiko Kruse deals with numerous technical enquiries each day from customers, branches, sales personnel and other areas of the company. For this role, the career changer can draw on his many years of experience in hydraulics.

Heiko, what does a technical adviser at HANSA‑FLEX actually do?

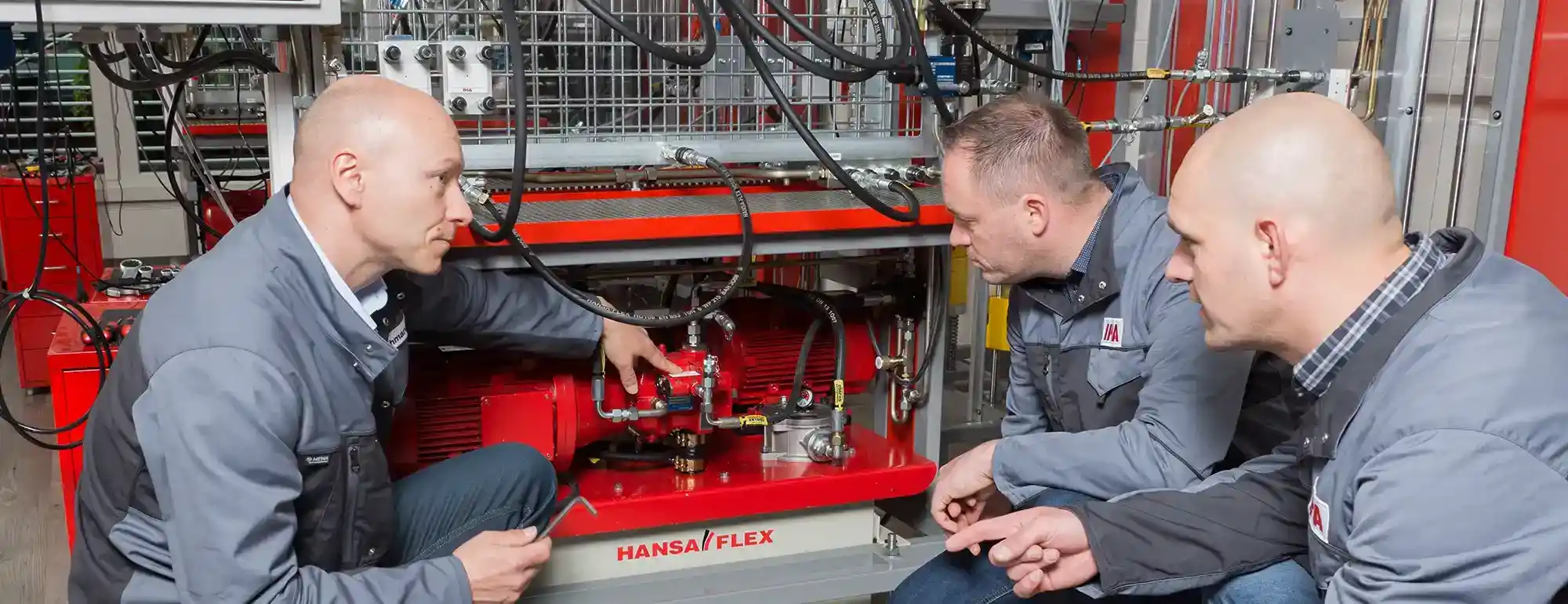

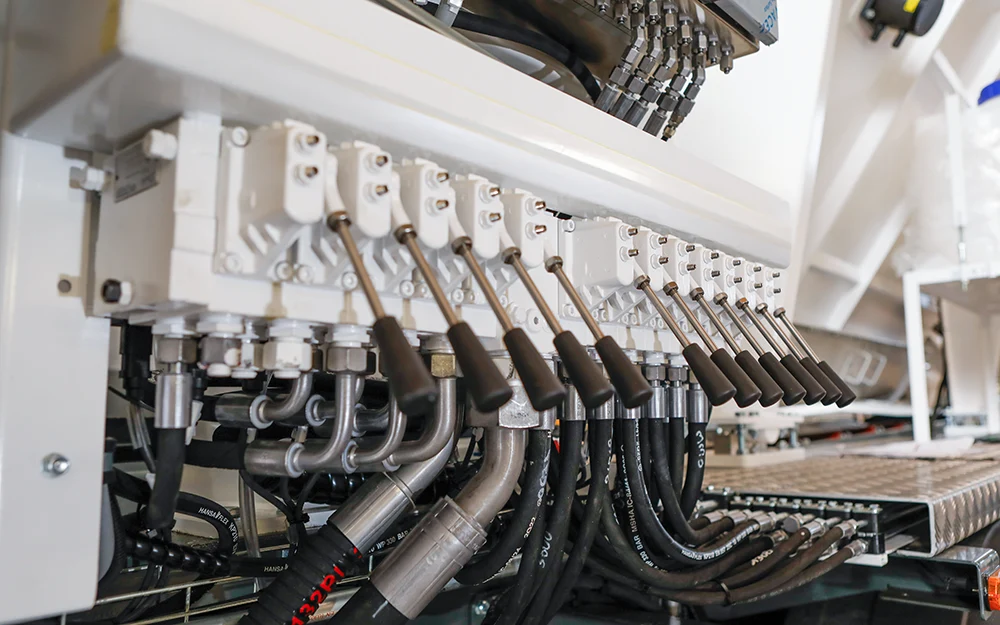

As a technical adviser, I form the link between the customer on the one side and our branches, specialist areas, sales personnel and headquarters on the other. If the discussion goes beyond traditional hydraulic hose lines, that is when I get called in. Hydraulic power packs, valve blocks, cylinders, pumps or complete hydraulic systems are my forte. I assess enquiries technically and design new or modify existing components. You could say: I am responsible for everything “to the left and right of the hose”.

Where do you do your work – at your desk or out and about?

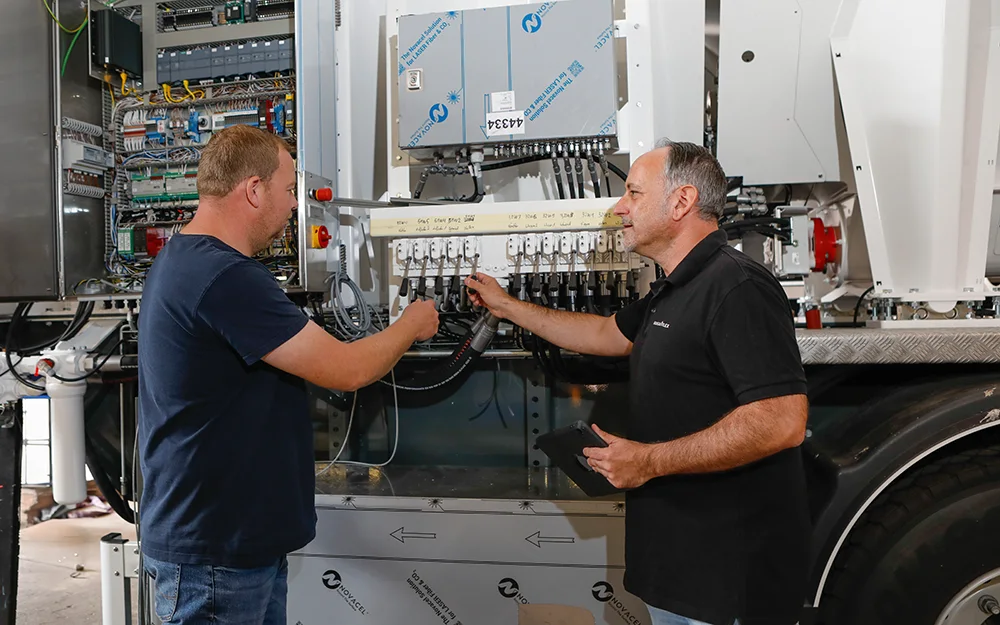

Both! Most of it starts off at the PC. I receive many enquiries by email, often with photographs of components that I am asked to assess or replace with alternatives. Sometimes a query can be resolved quickly on the phone. However, as soon as it becomes more complex, I am happy to drive to the customer’s premises. When you are on site, you can see the whole machine or system, better understand how everything works and speak directly with the customer or the technicians. This generally leads to a much quicker and more practical resolution.

In concrete terms, how you go about it?

Customer queries are as diverse as their industries. There is no routine method that suits all situations. Many technical questions cannot be answered only by studying datasheets. I have to understand the complete system in order to find the appropriate solution. That is the case not only for the design of new hydraulic components but also for the identification of potential sources of failure.

What do you like most about your job?

The variety! Even after more than 25 years in hydraulics, I am always learning something new. Every project is different, no two days are alike. I love solving technical problems, extending my skills and working with a wide range of people at the same time. And the occasions when everything cannot be planned in advance provide a vital stimulus for me. I look forward to getting into the car every morning, not knowing what the day will bring. To me, it is intensely motivating.

How do you find working with your colleagues?

The beauty of my job is that I get to work with a wide range of people from various company areas and different HANSA‑FLEX locations practically every day. For example, if it is something to do with hydraulic power packs, I work closely with our colleagues at Vechta, where Willmann design and build them. For particularly tricky challenges, I also discuss the matter with the experts at the International Hydraulics Academy (IHA). Then there are the questions from our Industrial Service. Rather than being purely technical, the questions often entail bringing different perspectives together and working with others to find the best solution for the customer. This is particularly important at HANSA‑FLEX: we all bring our own special abilities to the task in hand. Discussions take place with everyone on an equal footing, which leads us and therefore our customers to the right solution.

What else is particularly important?

I probably know almost every HANSA‑FLEX employee in the region. In addition to passing on technical information, I also see personal contact as very important. As technical advisers, we are a kind of feedback box for our colleagues because of our deep networking within the company. I am delighted to fulfil this role, which sometimes also extends to explaining the reasons behind decisions on specific matters by headquarters or senior management. To me, it is important for everyone to be on board because only together can we develop further as a company.

Which projects in particular stick in your mind?

A difficult question. I am always happy when I can contribute to satisfying our customers. Sometimes it’s the details that decide whether a machine or system works optimally and satisfies relevant criteria such as economy, energy efficiency and reliability. One memory of a major project that stays with me is the Kaiserschleuse sea lock at Bremerhaven. I was asked whether we could supply two hydraulic cylinders, each weighing over 12 tonnes. It is not every day that you get to work with objects of this size. To cut a long story short: using our international network, I was able to find a supplier for these special cylinders.

How did you become a technical adviser?

My career path has been anything but a straight line. I come originally from the installation side and spent many years working as a fitter in the field on customers’ premises, where I saw almost everything and learned a great deal. “Learning by doing” was the motto, which has been reinforced with many training courses. I think it is admirable that HANSA‑FLEX gives career changers like me an opportunity. There is, after all, no substitute for practical experience. I actually applied to be a sales representative but my regional manager, Thomas Hellmann, had other plans for me. I am still thankful to him today for his wisdom.

How do you switch off after a rich and varied working week?

During the week, I try to take part in regular sporting activities. The frequent trips my partner and I make to the Baltic Sea are a real treat at the weekend. There I simply relax, step back and recharge. Looking out over the sea across the broad horizon never fails to fascinate me. After these weekends, I return with a clear head to tackle the next challenge.

Mexico

Mexico