Extremely high-pressure hoses for applications up to 3,200 bar

Fields of application for HANSA‑FLEX extremely high-pressure hoses

Extremely high-pressure hoses for the oil and gas industry

Thermoplastic high-pressure hoses are very common in the oil and gas industry. As well as a high resistance to chemicals, thermoplastic hoses exhibit low volumetric expansion and are resistant to external pressure. They are typically used to carry gas and nitrogen and for the injection of chemicals and grease.

Extremely high-pressure hoses for hydraulic applications

Extremely high-pressure hoses for hydraulic applications are used, for example, for controlling hydraulic components, bolt tightening and torque application tools and in instrumentation equipment. Extremely high-pressure hydraulic hoses from HANSA‑FLEX combine great strength with flexibility.

- Light and flexible

- Highly load resistant

- Resistant to ageing, ozone and UV light

Extremely high pressure hoses for water jet applications

High-pressure water jetting is used to clean sewers and pipes as well as for the general cleaning of surfaces. Other important fields of application include water jet cutting and concrete surface refurbishment. HANSA‑FLEX offers a specially developed range of extremely high-pressure hoses for pressures up to 3,200 bar.

- Highly load resistant

- The highly abrasion-resistant hose outer cover results in a long service life

- High impulse load strength

Extremely high-pressure hoses in certified quality

Thermoplastic extremely high-quality hoses with pressure carriers incorporating spirally wound steel wire impress with their quality, service life and reliability.

-

Available variants

Available with internal diameters of 3 mm to 25 mm, these hoses can be used for pressure ranges up to 4,000 bar

-

Robust and flexible

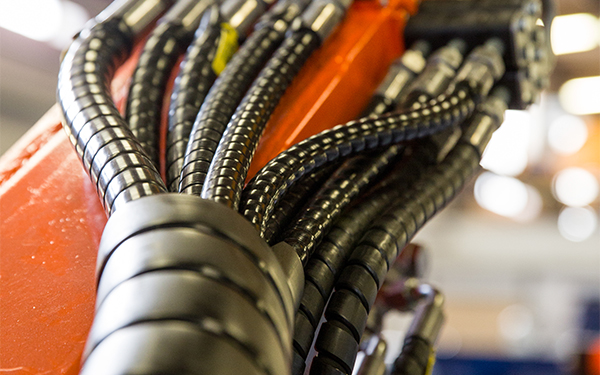

Two to eight layers of wire braid, reinforced version and with open spiral layer.

-

Customised solutions

Suitable fittings and accessories in any length

Extremely high-pressure hose lines from the hose professionals

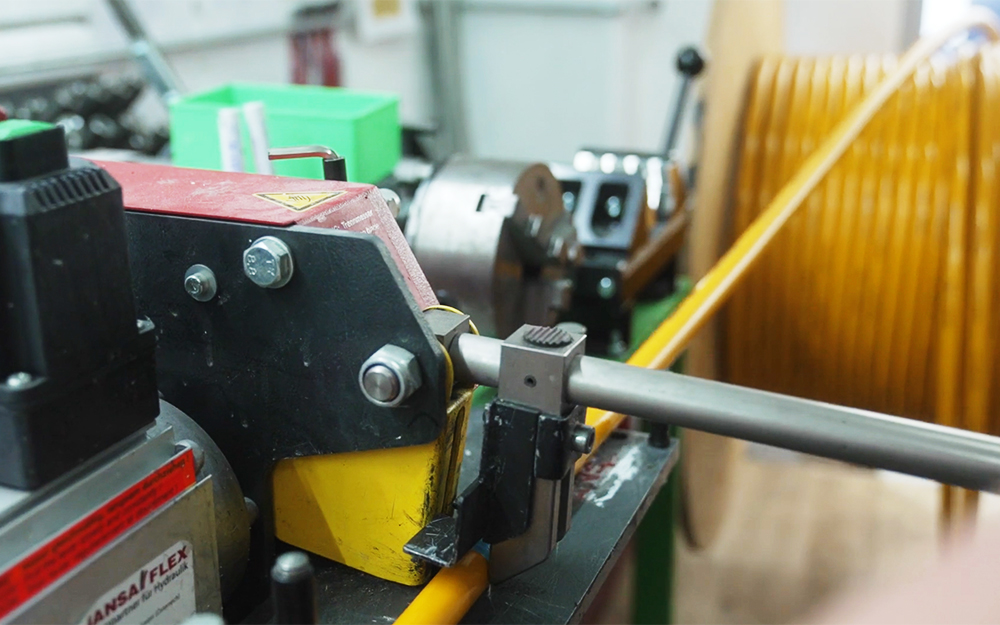

We know what matters when working with extremely high pressures. The highest material and manufacturing quality is guaranteed at HANSA‑FLEX.

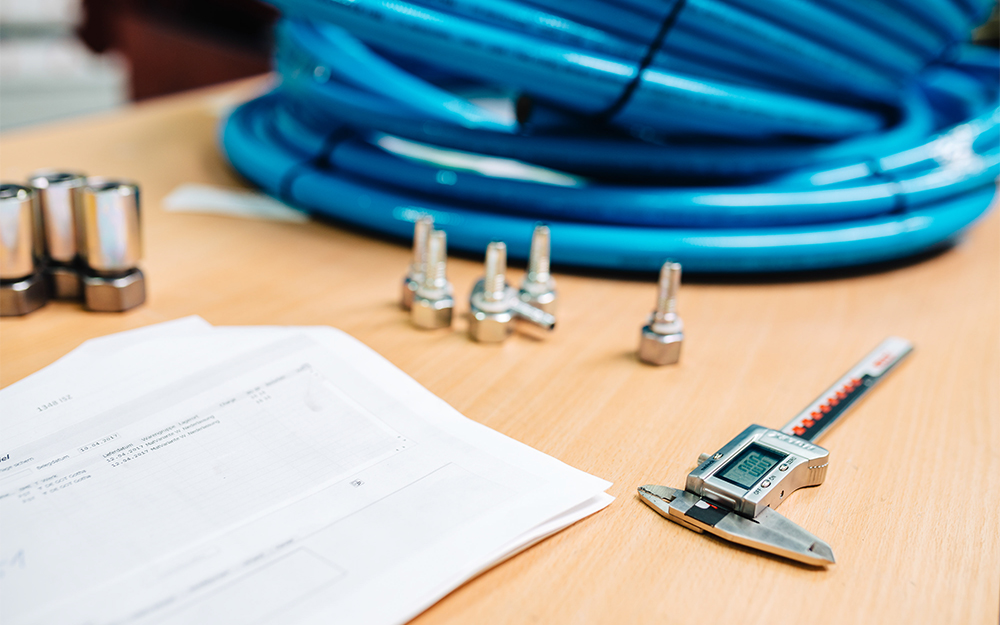

You can expect the usual high-quality products and services from the well-trained HANSA‑FLEX staff, who are also able to advise you on material choice, dimensions, fittings and bringing your systems into use.

- Comprehensive range of production machinery and equipment

- Customer-specific manufacturing by experienced specialists

- Multi-stage quality control including pressure tests

These topics may also be of interest to you

Components for high-pressure hydraulics up to 700 bar

HANSA‑FLEX offers a selected range of products for heavy-duty hydraulics with pressures up to 700 bar and can supply customised components for up to 1,000 bar.

Hose fittings for hydraulic applications

HANSA‑FLEX hose fittings are designed to perfectly match the hydraulic hoses. They also receive a zinc-nickel surface coating as standard.

Compatible accessories for hose lines

In addition to first-class hoses, the HANSA‑FLEX portfolio of accessories includes rubbing, heat and kinking protection devices and safety equipment such as hose restraints.

Highest standards of quality and safety

Reliability and safety confirmed by testing are essential when working with extremely high pressures. To guarantee this is the case, HANSA‑FLEX relies on high-grade materials, comprehensive testing and precise processing.

These topics may also be of interest to you

PTFE hoses with high chemical resistance

Because of their high chemical resistance against most media, PTFE hoses from HANSA‑FLEX are the first choice for all challenging applications.

Metal hoses with high temperature tolerance

Metal hoses excel in particular with their ability to withstand high mechanical loads, strength under vacuum and high temperature tolerance.

Industrial hoses in the highest quality

HANSA‑FLEX can produce industrial hoses to individual customer requirements quickly and competently in its own specialist hose workshop.

Mexico

Mexico