Flanges from HANSA‑FLEX

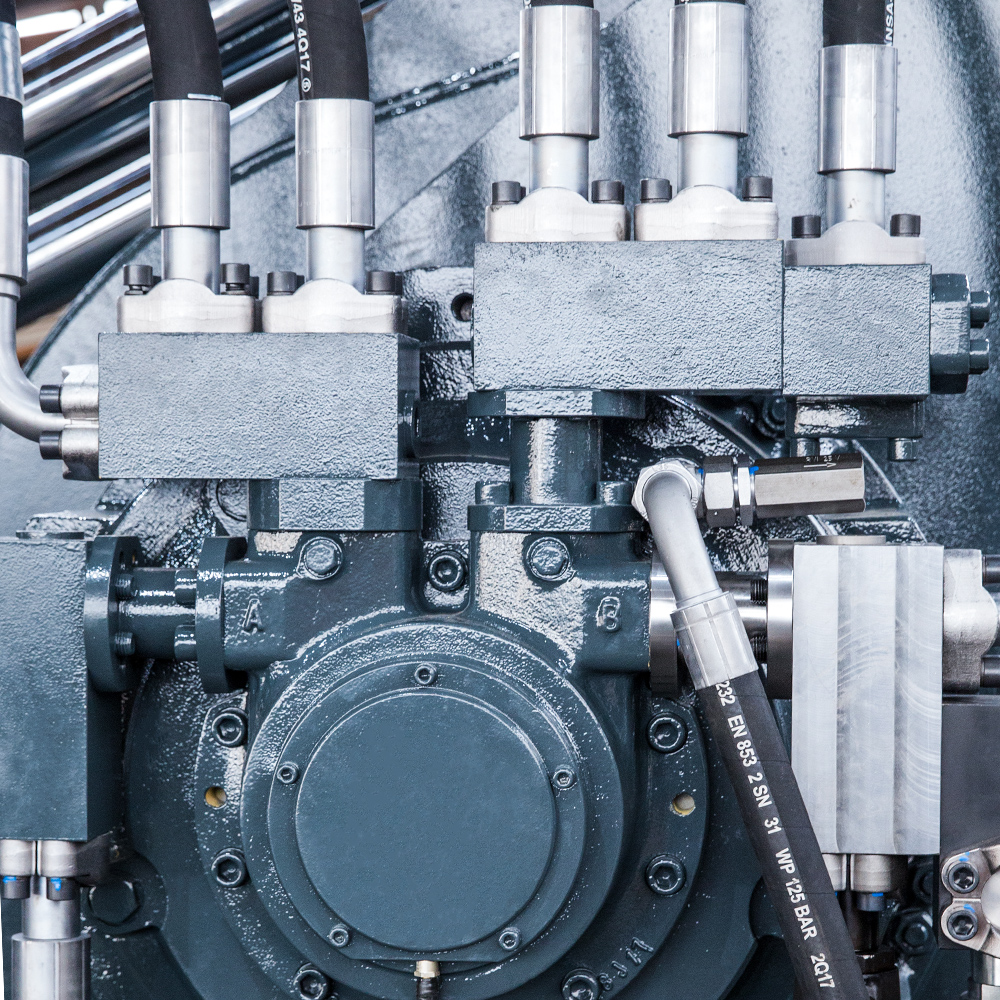

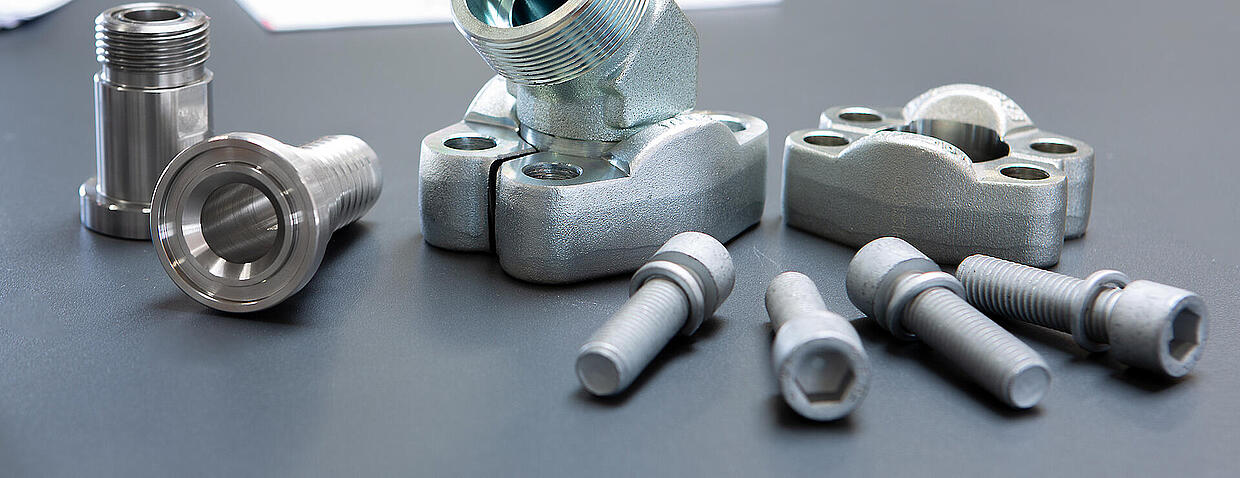

Flanges in accordance with SAE, ISO, CETOP requirements and gear pump flanges

All HANSA‑FLEX flange connections are available in various types, such as adapter and fixed flange, block, welded and soldered connections.

SAE flange

SAE flanges are available in two pressure classes: 3000 PSI in nominal diameters ½” to 5” and 6000 PSI from ½” to 3”. All SAE high-pressure flanges are manufactured in steel or stainless steel designation number 1.4404.

- Working pressure up to 420 bar

- For standard & high-pressure applications

- Untreated surface or galvanised zinc plated

ISO 6164 and CETOP flanges

We can provide you with our HANSA‑FLEX ISO 6164 flanges and CETOP flange connections in nominal diameters of ½” to 5”. All ISO 6164 and CETOP flanges are available in steel designation number 1.4404.

- Working pressure up to 420 bar

- Nominal diameter between DN 13 (1/2”) and DN 127 (5”)

- Stainless steel and alternative sealing materials on request

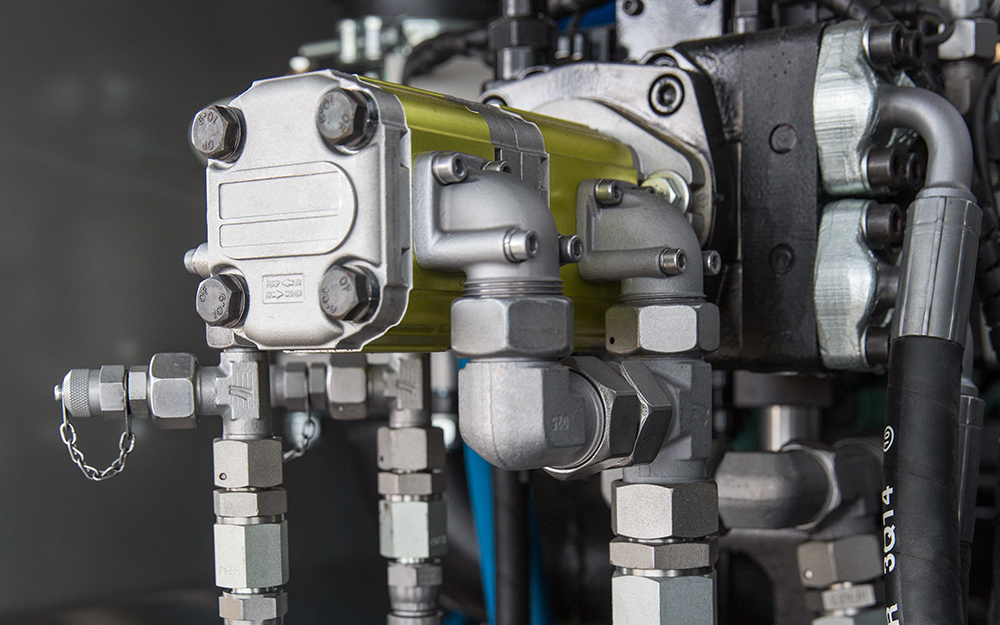

Gear wheel pump flanges

In addition to a metric external thread in accordance with DIN 3901 in sizes L8 – L42 and S6 – S38, we also offer pump flanges with inch internal threads in two construction variants (round, square).

- High-quality zinc-nickel coating

- Straight and 90° versions, each with pitch circles 30 to 55

- In steel or aluminium

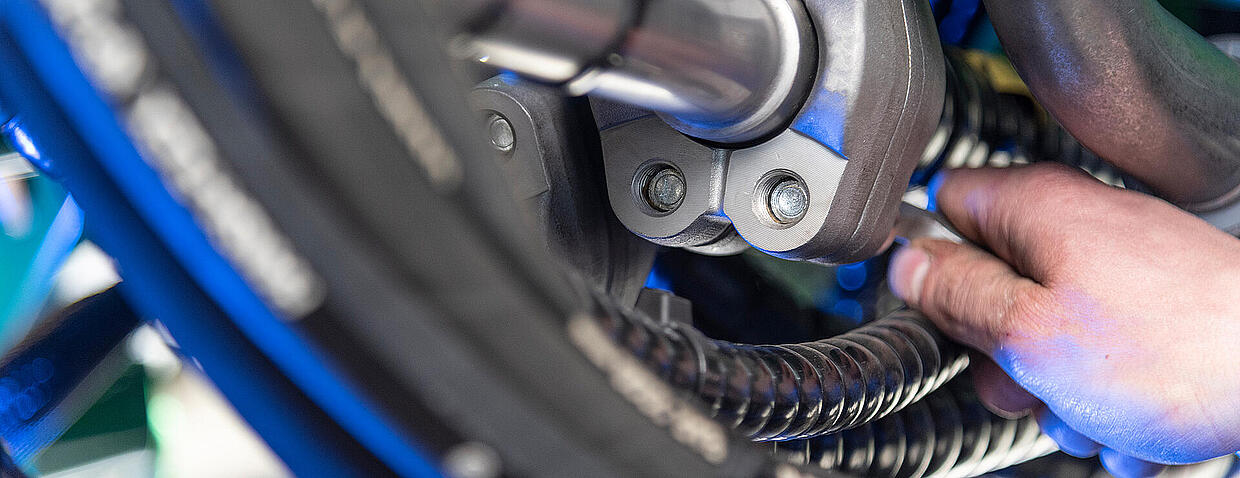

Flanges are a higher class of pipe connection

It is the connection technique most suitable for pipelines under highly dynamic loads, high working pressures and in tight installation spaces

-

Robust material

Suitable for high working pressures and highly dynamic loads

-

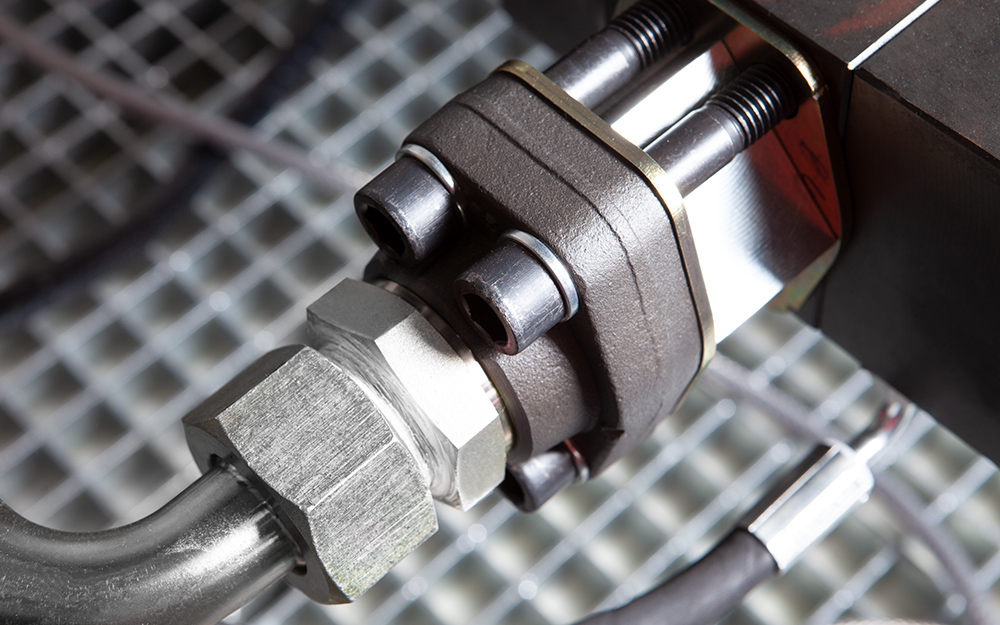

Pressure-resistant design

The sealing surface has a flat face, reliably sealed using O-rings

-

Releasable connection

The two flange halves can be disassembled and reassembled without damaging the components

-

Safe operation

Leak-free connection of pipes and components in hydraulic systems

The advantages of HANSA‑FLEX flange connections

HANSA‑FLEX flanges are stable under pressure, do not leak and suitable for tight installation spaces.

Purchase flanges online from the HANSA‑FLEX online shop!

Discover the flange connection product portfolio from the system provider HANSA‑FLEX

- Four-hole flanges, high-pressure flanges, pump flanges

- Flange halves, full flanges screw-in and welded on flanges

- For applications up to 420 bar and available in all common sizes

- Black oiled, steel, stainless steel, metric, inch

- Electroplated

- All threads and connections to SAE, NPT, BSPP, UNF, JIC, CETOP

You cannot go wrong with HANSA‑FLEX flange connections

Meets all standards and guidelines

Flange connections from HANSA‑FLEX meet the requirements of relevant standards such as ISO 6162, SAE J 518 C, DIN 3901 / 3902, ISO/DIS 6164 and other international guidelines. All flanges are designed with international market requirements in mind. Consequently we make regular adjustments to the product portfolio to allow for specific further developments.

- Manufactured in accordance with international standards and guidelines

- Portfolio development in accordance with market requirements

- Reliable delivery on time and, if required, in sequence

High product quality

HANSA‑FLEX ISO 6164, CETOP and SAE flange connections are available in steel and in stainless steel designation number 1.4404, with a galvanised zinc coating. Gear wheel pump flanges are available in aluminium or steel with a high quality zinc-nickel coating. This provides 720 h corrosion resistance against red rust.

- Materials: steel, stainless steel and aluminium

- Surface finish: galvanised zinc, zinc-nickel coating

- Welded or forged version depending on flange type

For all fields of application

Flanges are mainly used where pipe fittings are inappropriate because of their size, the required working pressure or lack of available space. We have a wide product portfolio for every field of application in fluid technology, such as industrial, mobile or marine hydraulics.

- Plastic injection moulding and aluminium die casting plants

- Hydraulic presses, lifting and conveyor equipment

- Construction, agricultural and forestry machinery

These topics may also be of interest to you

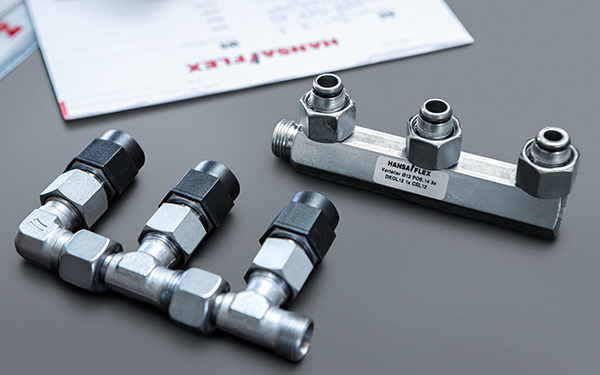

Leak-proof positive connection with standardised pipe fittings

HANSA‑FLEX pipe fittings rely on a tight positive fit with one another to create a safe connection, even when subjected to high working pressures, pressure peaks and vibrations.

Special fittings and pipes as one-off, small batch or series manufactured items.

In the HANSA‑FLEX manufacturing centre for special pipes and fittings, components are made with computer-controlled precision for OEM or replacement part applications.

Made-to-measure bent pipes

The HANSA‑FLEX pipe bending centre can produce bent pipes either individually or in batches. Its services also include computer-aided feasibility tests and 3D representations.

Mexico

Mexico