![[Translate to Germany - German:] Dokumente für Prüfung [Translate to Germany - German:] Dokumente für Prüfung](/fileadmin/_processed_/b/3/csm_Services_Pruefungen_07_e7e5b0b262.jpg)

HANSA‑FLEX is your reliable partner for inspections

Work equipment and operating materials reliably inspected with HANSA‑FLEX

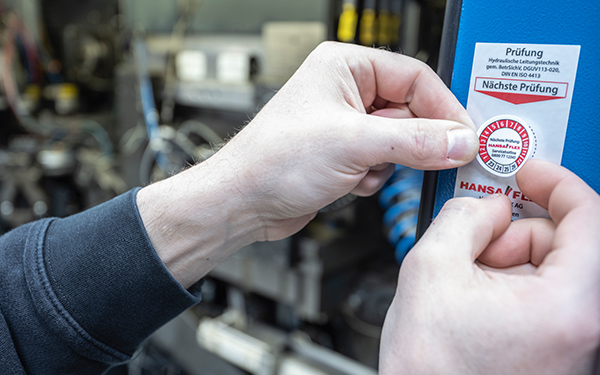

The trained and certified experts at HANSA‑FLEX perform the regularly prescribed inspections of hydraulic systems including documentation.

Inspection of industrial hoses

We inspect industrial hose lines carrying chemicals, foodstuff, pharmaceuticals and other media including the preparation of the legally required inspection certificate.

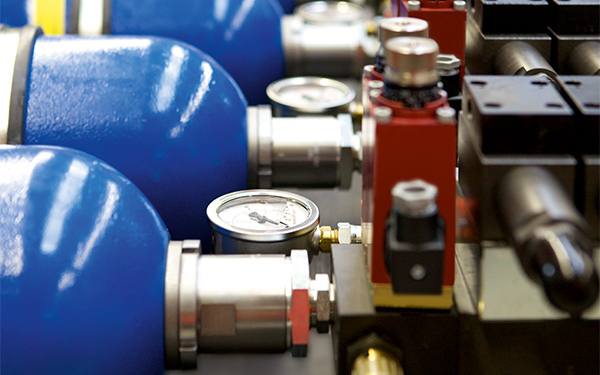

Inspection of pressure accumulators

HANSA‑FLEX employees are officially authorised persons for pressure accumulators and perform the legally prescribed visual inspection of pressure accumulators for you.

Inspection of lifting platforms and loading bridges

The experts at HANSA‑FLEX are officially authorised persons for lifting platforms and loading bridges and perform the annual inspections of this equipment for you.

Safer operations through preventive maintenance

The German Industrial Safety Act calls for ongoing regular inspections of work equipment such as machines in addition to the inspection performed before bringing them into first use. In this way, damage due to wear can be detected in good time and rectified. The inspections are to be arranged by the operator of the work equipment.

Legally compliant documentation based on inspection records

Scope of documentation

As part of the inspection, our experts document all the results in a clear and legally compliant manner for you. All the customer’s data and information about the system or machine are collected on our standard record sheets so that there is no doubt later about the details of the inspection. The documentation gives you information about:

- All the performed inspection tasks

- The date of the next inspection

- Any defects or abnormalities

Creation of the documentation

The documentation includes photographs of the system or machine to be inspected, such as photographs of the identification plate or particular construction features as verifiable evidence of its general condition. Any defects are photographed and filed. The photographs are a constituent part of the documentation and are sent to you together with the inspection sheets in digital form after completion.

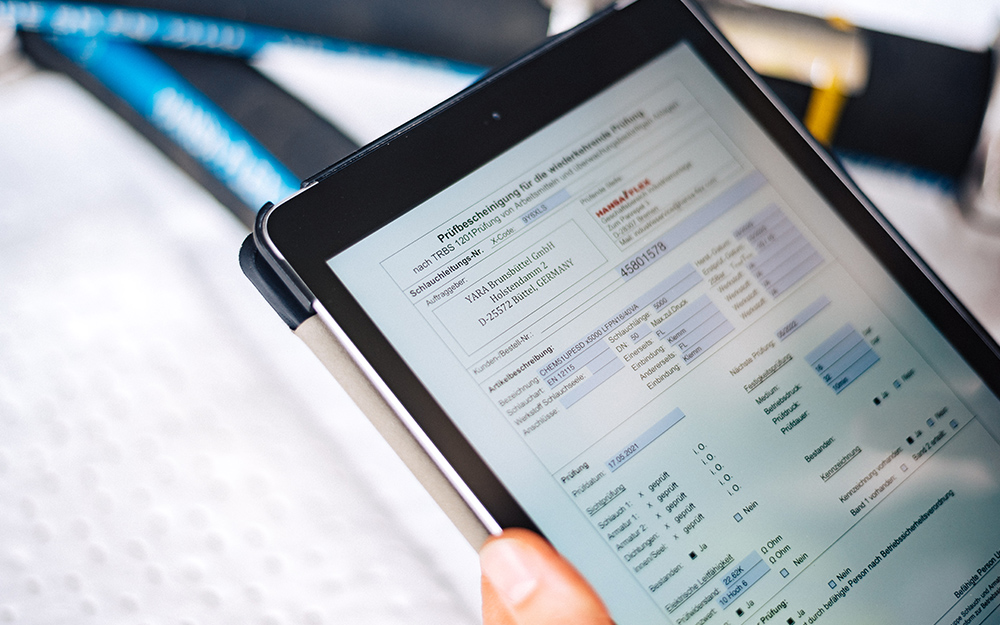

Digital data capture and management with X-CODE Ma

The documentation of the inspection of hydraulic hose lines is done in our hose management software. All the important information about every single hose line is stored there:

- Unique identification by X-CODE

- Manufacture, installation and, if necessary, replacement

- Risk assessment and inspection interval

Comprehensive service for your systems and machines

Our employees are experienced fluid specialists and support you with all tasks to do with the servicing, maintenance and overhaul of your pneumatic and hydraulic systems.

-

Ready for use again

The fluid experts overhaul defective hydraulic components such as cylinders and pressure accumulators

Mehr erfahren -

In good condition

HANSA‑FLEX Industrial Service supports you in your servicing and maintenance work

Mehr erfahren -

Oil care made easy

Avoid oil-related damage with the benefit of know-how from HANSA‑FLEX fluid experts

Mehr erfahren -

Smart hose management

With X-CODE Manager you have a complete picture of your hose lines, machines and inspection dates

Mehr erfahren

Better safety and service with HANSA‑FLEX

Comprehensive services all from the same provider

We are your service partner for everything to do with the inspection of hydraulic work equipment. We support you in the following tasks:

- Performance of inspections including documentation

- Advice and assistance in the preparation of risk assessments

- Installation and removal of the components to be inspected

- Replacement and overhaul of defective components

- Advice on the optimisation of machines and systems

Always on the safe side

With services from HANSA‑FLEX you are better assured of legal compliance. When performing inspections, we make sure we comply with the legal requirements and document the results in an inspection record:

- German Industrial Safety Act (BetrSichV)

- Machinery Directive / EU Use of Work Equipment Directive 2009/104/EC

- European Pressure Equipment Directive (PED)

- Germany’s statutory accident insurance organisation (DGUV)

- Technical rules for Industrial Health and Safety (TRBS)

![[Translate to Germany - German:] Mitarbeiter checkt Maschine [Translate to Germany - German:] Mitarbeiter checkt Maschine](/fileadmin/_processed_/3/9/csm_Services_Pru__fungen_01_698526751e.jpg)

Authorised persons at HANSA‑FLEX

The experts at HANSA‑FLEX who perform the inspection of hydraulic and pneumatic work equipment are certified by independent testing bodies as having the relevant up-to-date specialist knowledge.

Unsere Mitarbeiter sind als befähigte Personen in folgenden Bereichen qualifiziert:

- Befähigte Personen für Leitungstechnik

- Befähigte Personen für Druckspeicher

- Befähigte Personen für Windenergieanlagen

- Befähigte Personen für Hebebühnen und Laderampen

- Befähigte Personen für Industrieschläuche

Mexico

Mexico