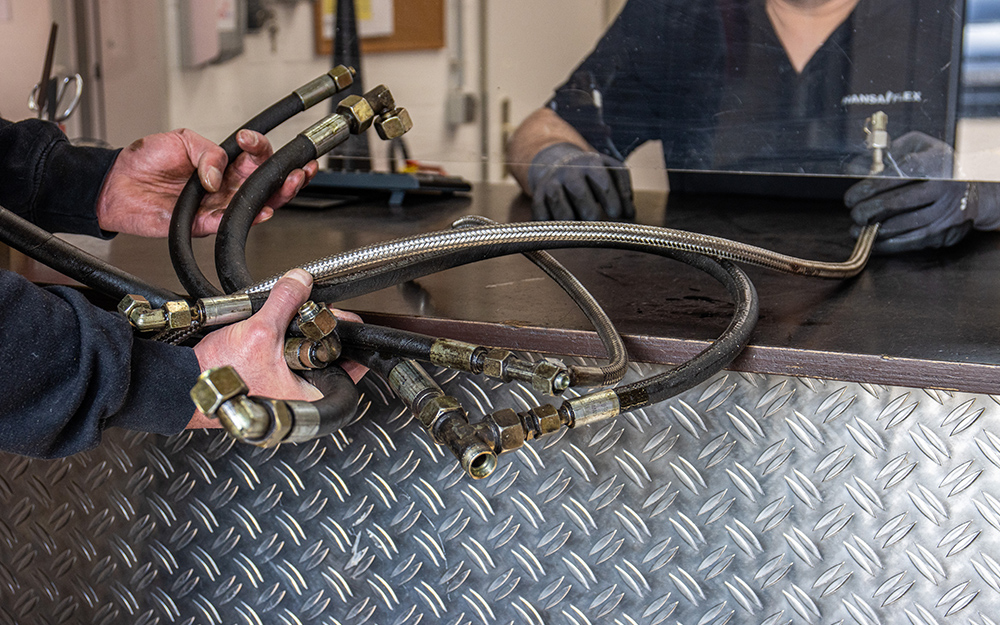

Inspection of hydraulic hose lines

Inspection by hydraulic hose line experts

As a fluid technology system provider, HANSA‑FLEX knows what has to be considered when inspecting hydraulic hose lines and offers a comprehensive service for everything to do with hose management performed by experienced and trained specialist personnel.

HANSA‑FLEX guarantees safety in accordance with the regulations

Hydraulic hose lines are regarded as work equipment in accordance with the German Industrial Safety Act (BetrSichV) and EU Use of Work Equipment Directive 2009/104/EC. In addition, hose lines are subject to high loads such as dynamic pressure changes and peaks during their everyday operation. Therefore hoses and connections must be regularly inspected to see that they are functioning correctly. The safety of personnel, systems and machines depends on hose lines being free of faults and defects. Inspection takes into account the DGUV rules and the German Industrial Safety Act (BetrSichV) as well as the relevant machinery directives. The experts at HANSA‑FLEX are familiar with all the applicable legislation and guidelines, so that all inspection complies with the legal requirements.

HANSA‑FLEX carries out all the necessary inspections.

Hydraulic hose line inspections must be performed at regular intervals in accordance with the applicable operational risk assessment, but at least every 12 months. The inspections may be carried out only by officially authorised persons for inspections. The HANSA‑FLEX experts have this qualification and can support you with the following tasks:

- Visual inspections and function tests

- Inspection taking into account changes requiring re-inspection

- Recurring inspections at the defined intervals

HANSA‑FLEX simplifies the task of documentation

Every inspection report must be recorded and kept safely until the next inspection. Depending on the number of hydraulic hose lines to be inspected, the obligation to prepare and keep inspection records can involve a lot of work for a company. As your service partner, HANSA‑FLEX takes over the recording and management of inspection results. Using the digital hose management platform X-CODE Manager, the machine operator and service technician can call up the latest information about every inspection for every system, machine and hose line.

Inspection by HANSA‑FLEX offers safety with added value

You can rely on a high level of expertise and comprehensive process knowledge for inspections with HANSA‑FLEX as your service partner.

-

Improved operational safety

Protection for users, systems, machines and your company’s reputation.

-

Reliable legal compliance

Comply with the legally prescribed intervals and retain legally compliant documentation

-

Higher availability

Avoid unplanned standstills and reduce component wear

-

More transparency

Have all your hose data and servicing dates ready to hand with the X-CODE Manager hose management platform.

Inspection focused on the customer’s needs

With all their many years of experience, the HANSA‑FLEX service technicians understand the individual requirements and needs of customers and see themselves as problem solvers.

Correct storage of hydraulic hose lines

In addition to inspection, HANSA‑FLEX provides comprehensive advice on the optimum storage of hydraulic hoses and hose lines in accordance with DIN 20066:2021-01.

Our experts recommend:

- Cool, dry, dust-free, out of direct sunlight

- Elastomers not below -10 °C

- Ideally between 15 and 25 °C at 65 % relative humidity

- Store horizontally and under no strain

- Maximum storage time for hose lines is 2 years

- Maximum storage time for hose material is 4 years

More services for hydraulic hose lines

For complete tracking of inspection intervals and results, it is advantageous for every hose line to have an individual code. X-CODE from HANSA‑FLEX is a practice-proven solution for coding when a new hose line is included and for follow-up coding of existing hose lines.

HANSA‑FLEX has decades of experience to call upon when advising customers on the principles of preparing a risk assessment report. This advice naturally includes the risk analysis in accordance with the EU Machinery Directive 2006/42/EC.

As operating equipment contaminated by oil, hydraulic hoses pose a considerable risk to the environment. Transport and recycling are therefore subject to strict legal requirements. Working with a certified waste management company, HANSA‑FLEX takes care of their professional disposal, including storage in tested collection containers and complete documentation.

Intelligent hose management from HANSA‑FLEX

More services for your hydraulic systems

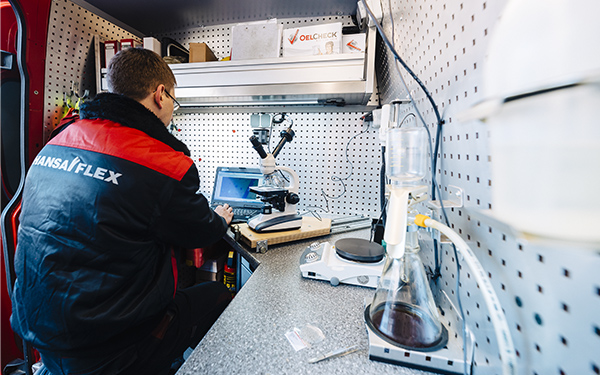

Testing of hydraulic fluids

HANSA‑FLEX Fluid Service analyses hydraulic oil for optimum fluid care. In this way problems are detected in good time and expensive standstills prevented.

Hose line management with X-CODE

The digital hose management system from HANSA‑FLEX contains all your hydraulic hose lines so that inspections can be completed more quickly and efficiently.

Rapid help in an emergency

Unplanned standstills must be dealt with as quickly as possible. The HANSA‑FLEX emergency service stands ready to do this all round the clock, 365 days a year.

Mexico

Mexico