Modern hydraulic systems incorporate stud ends with metric or imperial threads. The same applies to the ports. As these are not always clearly marked, confusion can easily occur during servicing or maintenance work; mix-ups which can have consequences.

Numerous hydraulic screw fittings are used in hydraulic systems. The diversity of these screw fittings is considerable: the wide range of different versions for the various pressure classes have numerous forms of connection, screw-in threads and seals.

Hydraulic screw fittings are used to connect the individual component groups and hydraulic components. They are subjected to ever higher working pressures as well as pressure peaks way above the design pressure. Working pressures of more than 500 bar are by no means unusual. Moreover, significant loads may arise from the working environment due to mechanical, thermal or chemical influences.

Background knowledge: How do threads actually differ?

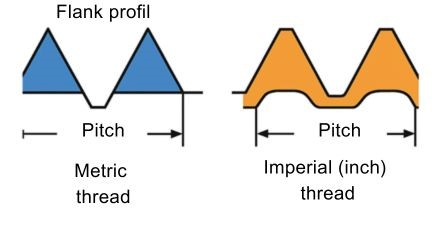

Screw fittings can be found everywhere with metric or imperial (inch) threads. The difference here is mainly due to the two systems of measurement, the flank profile and the pitch of the thread. The US-American Unified National (UN) thread series and the corresponding fine thread version Unified National Fine (UNF) are common across the Atlantic.

The flank profile describes the shape of the thread, in particular the angle between the flanks of the thread. The pitch describes the distance a screw moves in a thread in one complete rotation. For example, an M12x1.5 thread has a pitch of 1.5 mm. The screw moves 1.5 mm further into the threaded hole with each full rotation.

A standard series in the context of threads denotes a standardised series of threads with defined specific parameters such as diameter, pitch and tolerances. The standards ensure that threaded connections, such as nuts and bolts, fit together accurately despite being manufactured separately. The most well-known standard series is the metric ISO thread (M).

Not perfect, but it will do

According to the applicable statutory regulations, standards and rules, manufacturers and operators of systems and machines have the duty to ensure maximum safety during the operation of their equipment. An important prerequisite for this is the revision of DIN 3859 in its current form, which requires mandatory marking between metric and parallel imperial pipe threads (DIN ENISO228-1). The clear and unambiguous marking with a notch on the wrench flat of the imperial thread is intended to reduce the risk of confusion (Figure 2a). The transitional period for this ended on 31.12.2024. However, practice shows that there are still enough unmarked components on the market that are and will continue to be installed.

If the expert takes a close look at the hydraulic connecting elements, he will notice that not all connecting elements placed on the market are subject to mandatory labeling, partly due to the requirements of DIN 3859. FAs a result, many thread types are still very difficult to distinguish from one another due to their geometric shapes and dimensions, and can only be distinguished from one another using special measuring equipment or thread gauges (Figure 2b).

This being the case, the stud ends of hydraulic connection elements very often appear to fit into various standardised ports (Figure 3 and 4), although the connection they form is often unsafe and not reliable under pressure.

The threaded ports and stud ends of the connection elements often differ only in detail. Hence there is the danger that a hydraulic screw fitting with a G1/2” stud end can be screwed into an M22x1.5 threaded hole without any noticeable problem.

At first glance, the connection appears to fit. However, this connection with two different thread types cannot usually withstand the pressure and, in the worst case, comes apart. This can lead to serious injury and environmental damage. The consequential unplanned stoppages or repair downtimes should also not be ignored.

Less is more

The harmonised safety standard DIN EN ISO 4413 requires that all connection ports, stud ends and screw connections in a hydraulic system should be limited to as few standard series as possible. It is also worth a quick look at the reference documents, where a note expressly states: “If more than one ISO standard screw-in connection type is used in a system, then there is a great possibility of mix-ups taking place between some sizes of the various connection series, which gives rise to leakage and serious failure of the connection.”

As much as it may be desirable to have uniformity among the standard series used, in practice the picture is different. During maintenance, we often come across machines or equipment with a wide range of installed hydraulic connection systems. The risk of mixing up the thread types used and consequential major damage increases if the maintenance tasks are having to be done under enormous time pressure during machine downtimes. In addition: even if the machine manufacturer has observed the requirements in DIN EN ISO 4413, the risk of a dangerous mix-up in the hydraulic connection components remains while carrying out routine hydraulic maintenance activities. More about this in the following paragraph.

Caution – Danger of confusion!

Even though, for example, in the case of metric and imperial threads, the differences mainly relate to their units of measurement and pitch, they are so similar that a “mixed” assembly is still mechanically possible. For non-experts, this sort of mix-up is often not immediately obvious; the hydraulic connection appears “solid” and “pressure-safe”. When, however, the hydraulic system is placed under pressure, it can lead to the body of the fitting coming apart. As a rule, experienced personnel can identify the false mating of threads by the slightly greater play in the fitting when the screw connection is being made. However, not all personnel engaged in hydraulic system maintenance have this experience and familiarity with this behaviour during assembly. Therefore, we recommend that the possible risk of mix-ups and the associated dangers are pointed out to personnel during their necessary instruction provided by the employer.

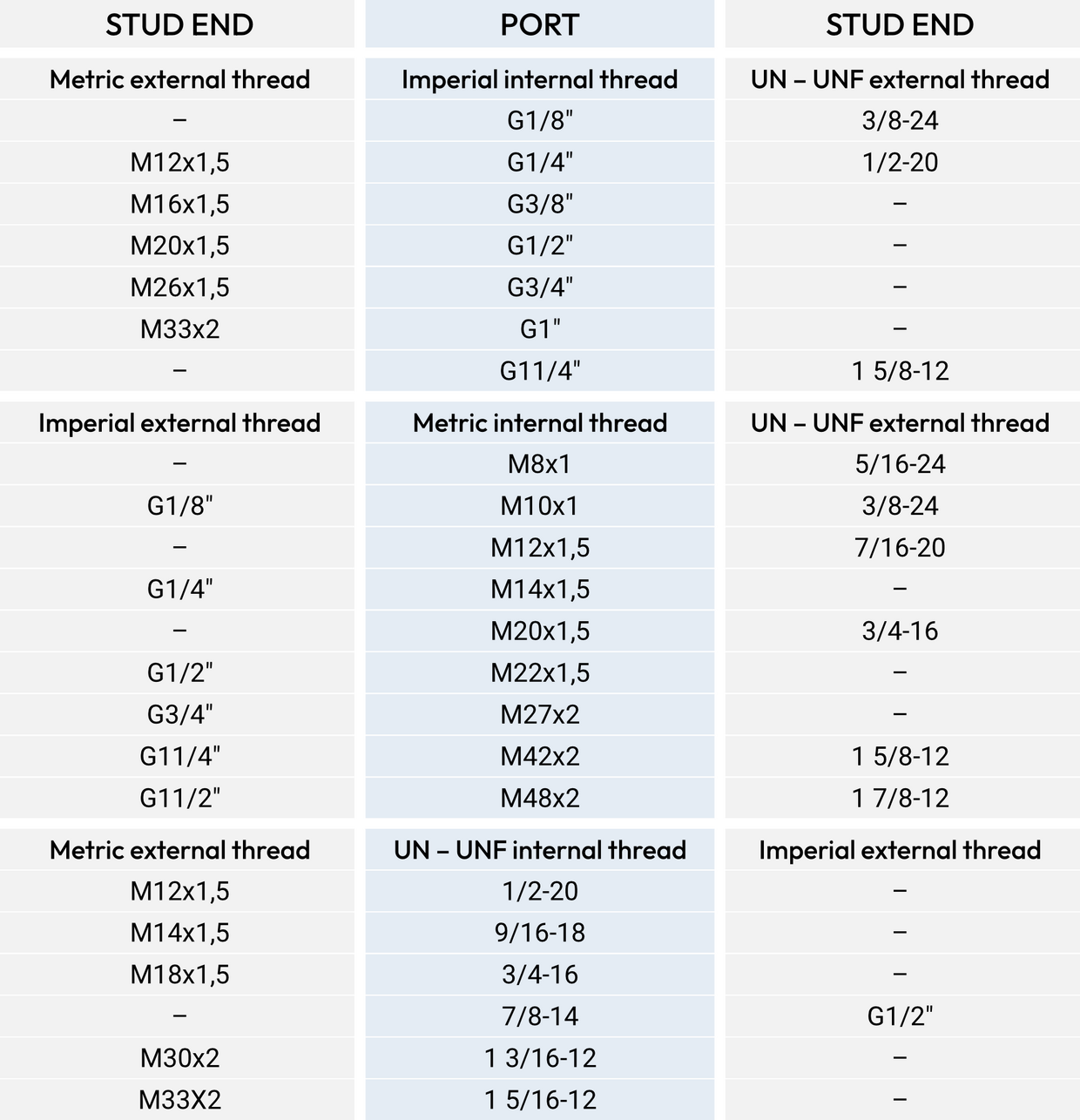

The following table shows the diversity of the various thread types and the resulting high number of possible risks of mix-ups.

Clear markings, clear knowledge

Potential sources of error can already be reduced in the design of new machines if, for example, screw-in ports are consistently marked, for example with an “M” for metric threads. Even if the relevant standards do not yet cover this type of marking, companies should voluntarily go down this path to simplify the later installation of their products. This step, in conjunction with the above-mentioned limitation to using the least possible number of different standard series, will minimise the number of problem locations in advance.

The use of standardised connection elements and similarly standardised threads and sealing forms to ensure correct assembly is self-evident. Also to be recommended is targeted training of installation and maintenance personnel on the topic of hydraulic threaded connection technology: A danger explained is a danger avoided.

-

![[Translate to Englisch:]](/fileadmin/hansaflex/News_and_Events/Online_Magazin/Technik/Autoren_IHA/ulrich-hielscher.jpg)

Ulrich Hielscher

Managing Partner, Trainer for line technology and hydraulic oils at the International Hydraulics Academy

Mexico

Mexico