Series production

Do you have any questions about our services and products? Or do you need help?

Sundays and public holidays are excluded

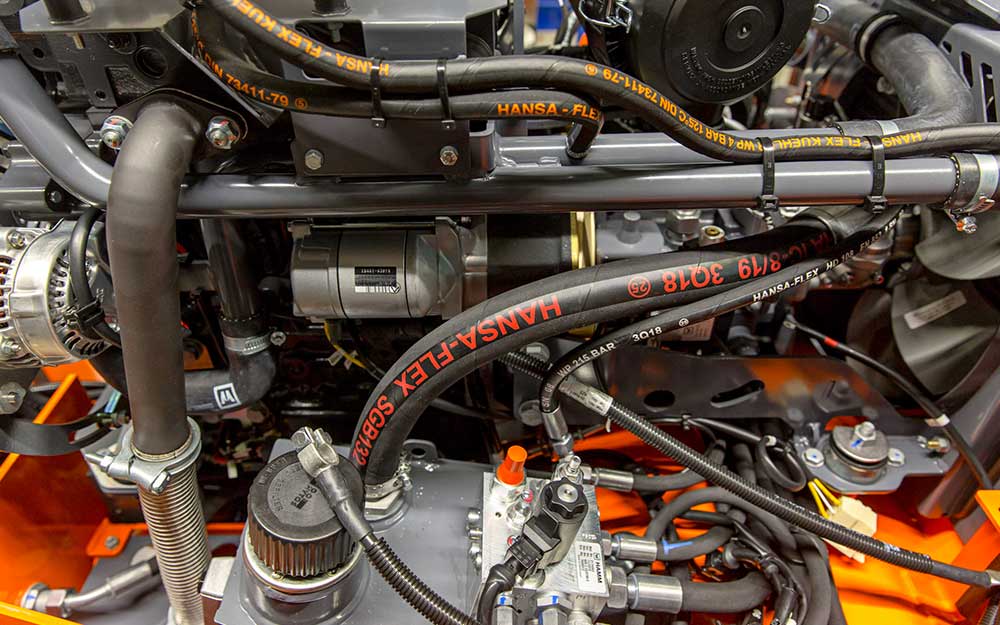

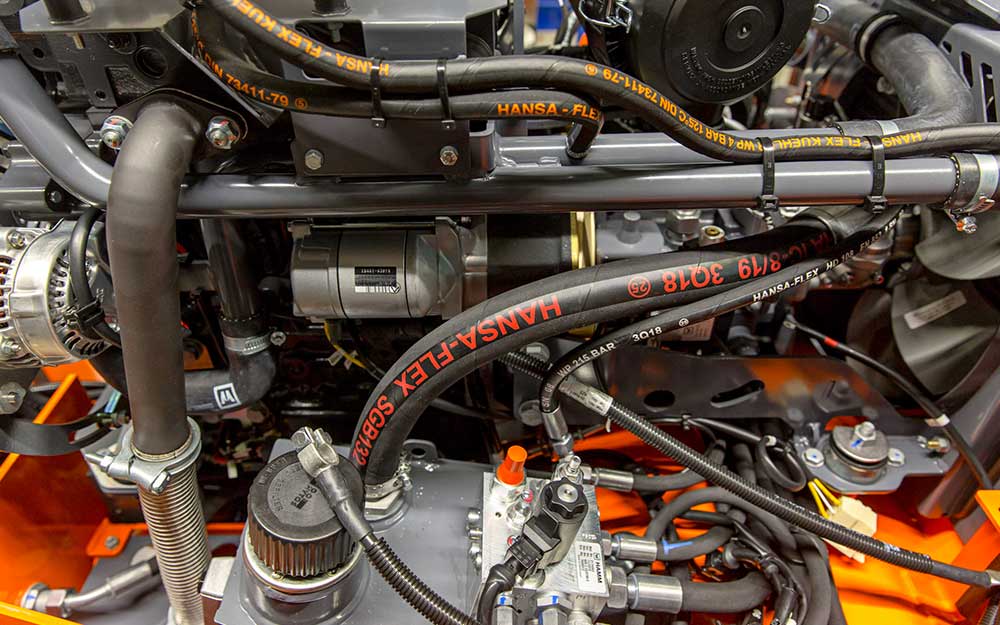

Hamm AG produces rollers for asphalting and earthwork operations

A hydraulically driven catapult launch makes the “Desert Race” roller coaster at the Heide Park Resort leisure park unique.

The Belgian firm of Fisheye creates extraordinary exhibits that come to life thanks to hydraulics from HANSA-FLEX.

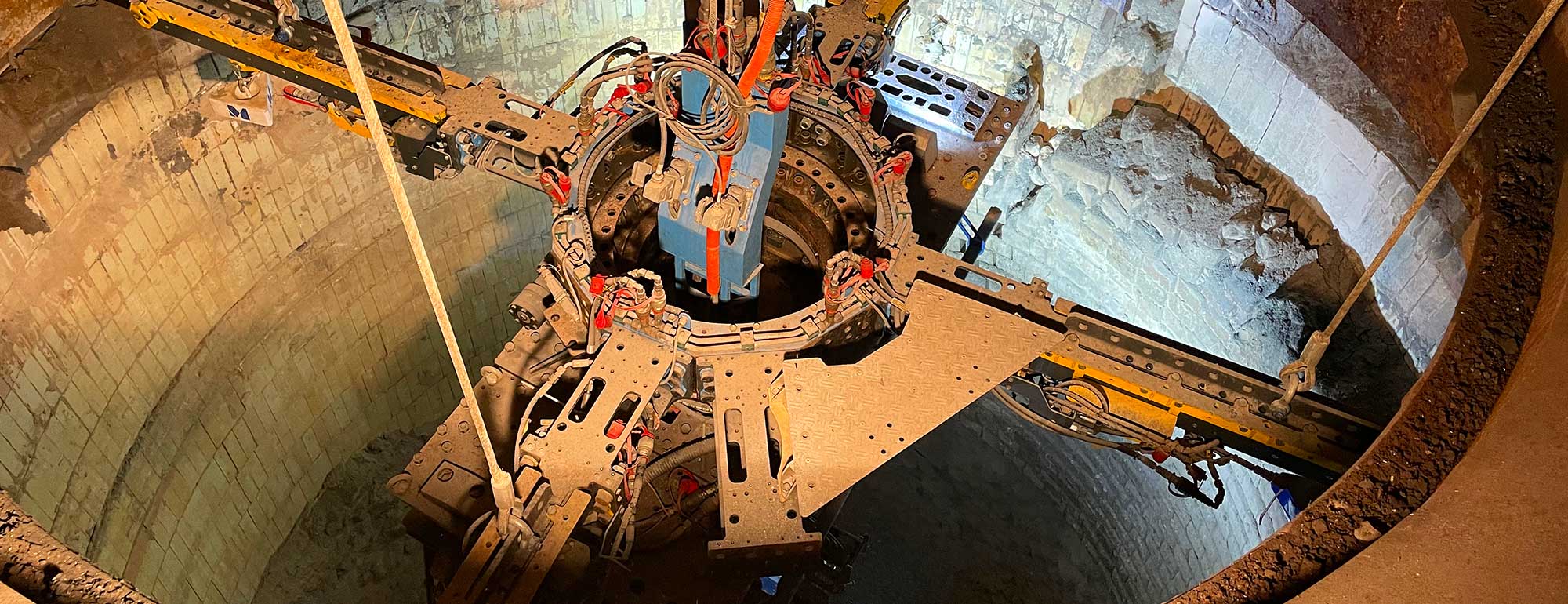

A remote-controlled robot on a mobile platform: the M-Group is revolutionising the maintenance of industrial furnaces.