The following step-by-step instructions refer to the use of the HANSA‑FLEX fluid extraction kit "HK FES PRPK". The kit comes in a practical case with all the components needed to take oil samples without contamination. The centrepiece of the kit is a vacuum pump with an adapter for the two supplied sample containers (100 and 250 ml) made of shatterproof glass. The suction hose can be cut precisely to the required length with the hose cutter, which is also supplied.

An oil analysis kit for organic oil and mineral oil is available separately, with which the water content and acidity can be determined and any mixing of various oils can be detected.

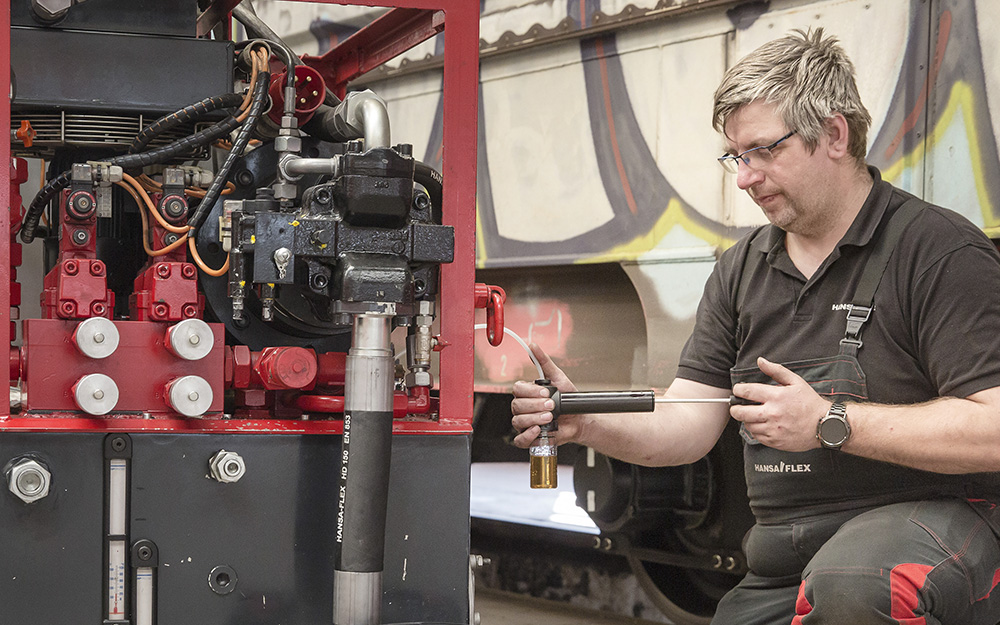

This is how it is done: taking oil samples yourself

2. Screw the appropriate adapter for the sample containers (DIN 38 or DIN 55 thread) onto the HANSA‑FLEX vacuum pump.

3. Take a sample container and screw the glass onto the vacuum pump.

4. Release the pinch clamp on the pump and push the hose through the head of the pump until the hose end projects approx. 1 cm into the sample container. Make sure you close the pinch clamp so that it holds the hose securely.

5. Cut the hose to the desired length using the hose cutter.

6. Place the other end of the hose into the sampling point. The hose must not touch the bottom of the tank at the sampling point, as there may be sludge and deposits there that could falsify the results of the analysis.

7. Pump the oil with approximately 3–6 complete strokes of the pump (depending on the size of the sample bottle) evenly into the sample bottle. Ensure that the sample container remains upright during the whole of the sampling process and is not overfilled.

8. Carefully unscrew the filled sample container from the adapter and seal the container with the lid.

9. Dispose of the used section of hose in accordance with the applicable regulations.

10. When sending the sample to our laboratory you should only use the HANSA‑FLEX oil analysis kit, which contains an approved shipping envelope, a plastic sample container and the necessary accompanying note.

11. The HANSA‑FLEX vacuum pump and adapter remain clean and can be re-used as often as required. Use a new suction hose and a clean sample container every time you take an oil sample.