What is meant by the term “persons qualified"?

-

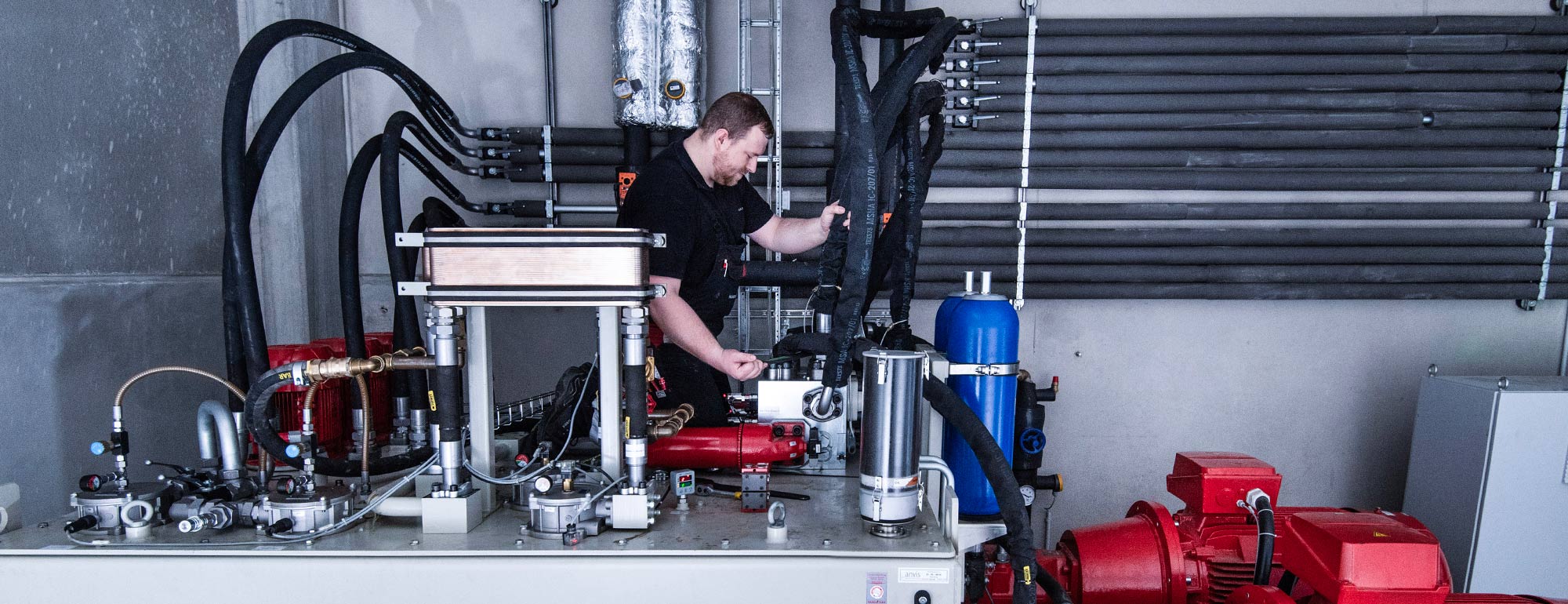

Daniel Werner

Instructor in line technology and pneumatics (IHA)

Do you have any questions about our services and products? Or do you need help?

Sundays and public holidays are excluded

Can this be performed by just anyone?

Instructor in line technology and pneumatics (IHA)

Caution – Danger of accident! What you need to know about the various thread types on hydraulic screw fittings.

The efficiency and performance of hydraulic systems in construction machinery depends largely on the valve technology used.

How to perform every task related to the management of hose lines quickly, easily and safely.