Masters of the soil

Hans Wübben GmbH tills and retills agricultural and forest land

Learn more

Clean oil, clean cement production

The HANSA-FLEX Fluid Service in operation at Holcim: how clean oil contributes to sustainable cement production.

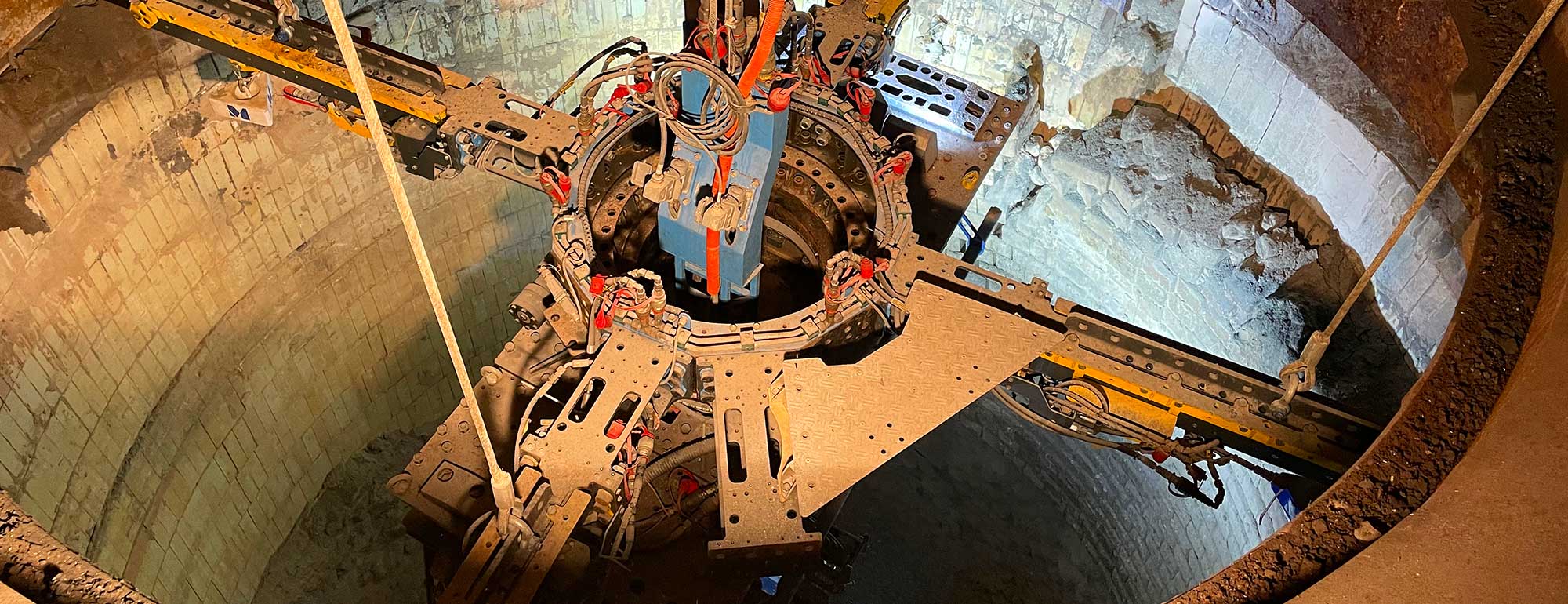

A digital revolution in industrial operations

A remote-controlled robot on a mobile platform: the M-Group is revolutionising the maintenance of industrial furnaces.

First air-conditioned S-Bahn trains in Berlin

HANSA-FLEX is a partner of Stadler Deutschland GmbH in the integration of air-conditioning lines in the first air-conditioned S-Bahn trains for the Berlin/Brandenburg region.